Gyroscope Sensor Guide: From Physics to Expert Engineering

Ever wonder how your smartphone instantly knows you tilted it while playing a racing game or taking a panorama photo? That magic comes from a tiny gyroscope sensor. A gyroscope sensor is a device that measures angular velocity and maintains an object’s orientation in 3D space, leveraging the Coriolis force for precise tilt and rotation detection essential for everything from smartphone gaming to aircraft navigation.

I’m Dr. Elena Tech, PhD in Electronics Engineering with over 15 years consulting for in reputable firms Today, I’ll walk you through everything you need to know about gyroscope sensors in 2025 from the physics behind the Coriolis force gyroscope to building your own project with an MPU-6050.

What is a Gyroscope Sensor?

A gyroscope sensor is a device that measures angular velocity how fast an object rotates around its X, Y, and Z axes using the Coriolis force. It detects yaw, pitch, and roll movements instantly and is found in almost every smartphone, drone, car, and VR headset in 2025. Think of yaw as turning your head left or right, pitch as nodding up and down, and roll as tilting your head side to side. These three axes give us complete 3D orientation.

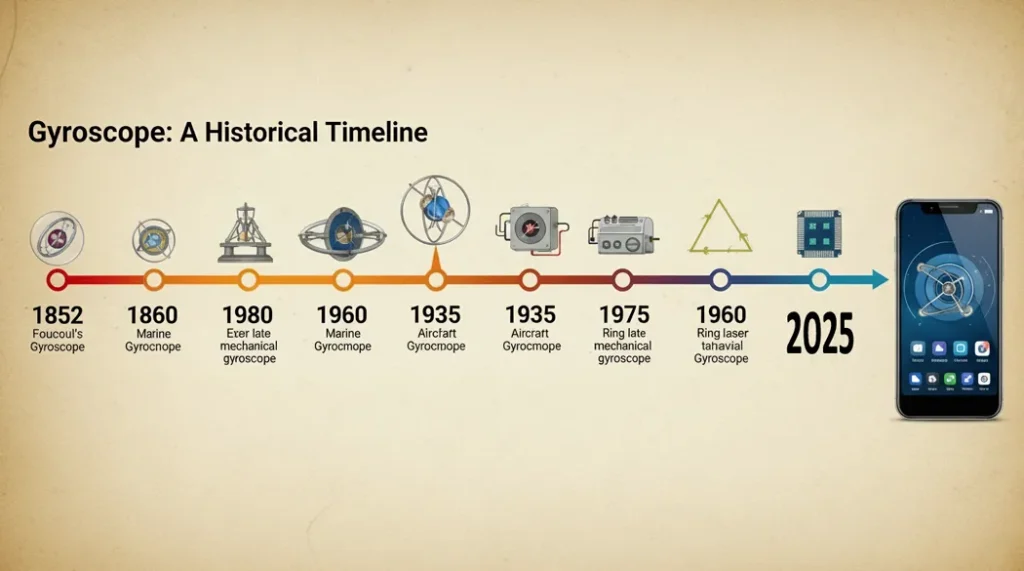

The journey began in the 19th century with mechanical spinning-wheel gyroscopes used in ships. Fast-forward to 2010 when Steve Jobs introduced the first consumer MEMS gyroscope in the iPhone 4, forever changing mobile gaming and augmented reality.

Gyroscope Sensor Working Principle

Gyroscope Sensor Working Principle

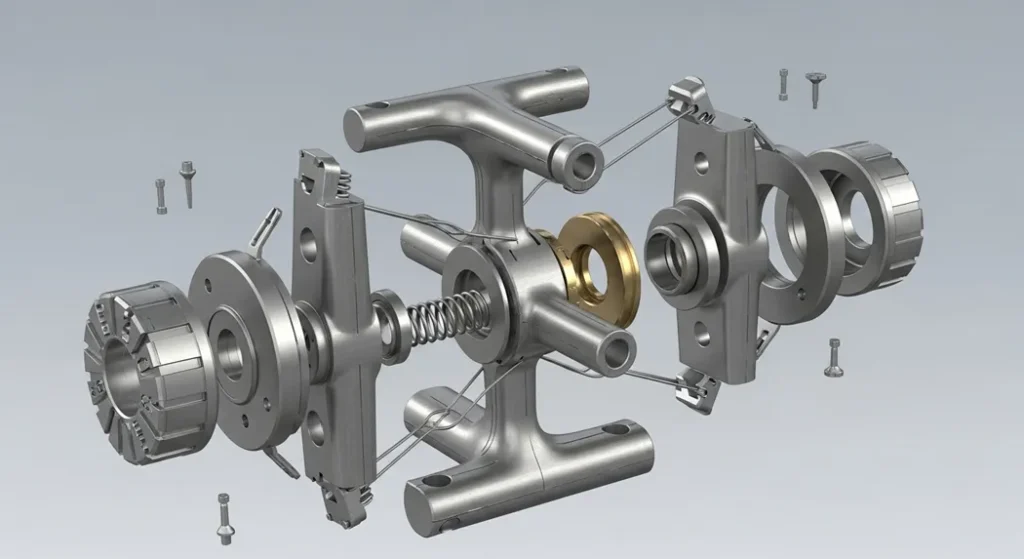

Understanding the gyroscope sensor working principle starts with two concepts most engineers first meet in physics class: vibration and the Coriolis force. A microscopic proof mass often shaped like a tuning fork or double-T structure is driven into constant high-frequency vibration using electrostatic or piezoelectric forces. When the sensor is stationary, this vibration remains perfectly symmetrical and produces zero net output. The instant the entire device rotates, the Coriolis force appears. This fictitious force deflects the vibrating mass perpendicular to both its vibration direction and the axis of rotation. The deflection is tiny (nanometers), but it changes the capacitance between interdigitated comb fingers. This capacitance change is amplified, demodulated, and converted into a clean voltage proportional to angular rate typically expressed in degrees per second (°/s).

Imagine a tiny tuning fork or double-T shaped crystal inside the chip. An alternating electrical field makes this structure vibrate at its natural resonant frequency (typically 10–30 kHz). When everything is perfectly still, the vibration stays symmetric and no net signal appears on the sensing electrodes.

Now rotate the entire chip. The Coriolis force a fictitious force that appears in rotating reference frames deflects the vibrating mass perpendicular to both the vibration direction and the axis of rotation. This deflection generates a measurable charge difference, which the sensor converts into an electrical signal proportional to angular rate.

The core equation behind every modern vibration gyroscope is:

Ω = a_c / (2 × v × sinθ)

Where Ω is angular velocity, a_c is Coriolis acceleration, v is the velocity of the vibrating mass, and θ is the angle between vibration and rotation axes (usually 90°).

Quantitative Analysis: Modeling Gyroscopic Error

In professional inertial navigation, understanding the mathematical error model of a MEMS gyroscope is more important than the sensor’s raw output. All gyroscopes suffer from two primary error sources: Bias Instability and Angular Random Walk (ARW).1. The Error Model Equation

The total measured angular rate ($\Omega_{meas}$) is modeled as:$$\Omega_{meas}(t) = \Omega_{true}(t) + b(t) + n(t)$$Where:- $b(t)$ = Time-varying bias (Bias Instability)

- $n(t)$ = White noise (leading to Angular Random Walk)

2. Calculating Angular Random Walk (ARW)

ARW defines the uncertainty in the angle ($\theta$) after integration over time ($t$). It is calculated using the Noise Density ($N$):$$\sigma_\theta(t) = N \cdot \sqrt{t}$$Engineering Insight: If your sensor has a noise density of $0.01^\circ/s/\sqrt{Hz}$, after 1 hour of integration, your heading could drift by several degrees. This is why high-end Fiber Optic Gyroscopes (FOG) are required for long-term navigation where GPS is unavailable.Complete List of Gyroscope Sensor Types Available in 2025

There are five major types of gyroscope sensors used today: MEMS vibration gyroscopes (used in 95%+ of consumer devices), Ring Laser Gyroscopes (RLG), Fiber Optic Gyroscopes (FOG), Hemispherical Resonator Gyroscopes (HRG), and the older Dynamically Tuned Gyroscopes (DTG).| Type | Typical Size | Bias Stability | Cost (2025) | Primary Applications |

|---|---|---|---|---|

| MEMS Vibration | 2–4 mm | 1–10 °/hr | $0.80–$5 | Smartphones, drones, wearables, cars |

| Ring Laser (RLG) | 10–40 cm | 0.001 °/hr | $15,000+ | Commercial aircraft (Boeing 787), missiles |

| Fiber Optic (FOG) | 5–20 cm | 0.01–0.5 °/hr | $800–$8,000 | Satellites, submarines, self-driving cars |

| Hemispherical Resonator (HRG) | ~30 mm | 0.0001 °/hr | $50,000+ | NASA deep-space probes |

Engineering Design: Selecting the Right Sensor Grade

Not all gyroscopes are created equal. When designing a system, an engineer must choose between Consumer, Industrial, and Tactical grades based on the required stability.| Metric | Consumer (Smartphone) | Industrial (Drones) | Tactical (Missiles/RLG) |

|---|---|---|---|

| Bias Instability | 20–50 °/hr | 1–10 °/hr | < 0.1 °/hr |

| Angular Random Walk | 0.5 °/√hr | 0.05 °/√hr | 0.001 °/√hr |

The “Scale Factor” Standard

A major deficit in basic tutorials is the mention of Scale Factor Error. Per IEEE 1431, the scale factor ($S$) is the ratio of a change in output to a change in the input. In professional systems, we must calibrate for the Thermal Sensitivity of this factor:$$S(T) = S_0 (1 + a \cdot \Delta T)$$Where $a$ is the temperature coefficient. Without this calculation, your drone or robot will lose its heading as the motors heat up the sensor board.Types of Gyroscope Sensors

Gyroscope sensors come in several fundamentally different designs, each suited to specific performance and cost requirements. Ring laser gyroscopes dominate aerospace because they offer extremely high accuracy with almost zero drift, making them ideal for inertial navigation in commercial aircraft. Fiber optic gyroscopes work on the Sagnac effect and strike a balance between precision and size for military and marine use.

At the consumer end, vibration gyroscopes especially MEMS gyroscope variants have become ubiquitous due to their microscopic size and low manufacturing cost. Within vibration gyroscopes, piezoelectric crystal designs (double-T or tuning-fork shapes) and ceramic prismatic structures lead the market. The MPU-6050, MPU-9250, and Bosch BMI088 all belong to this MEMS gyroscope family that powers 90% of today’s smartphones and drones.| Type | Typical Size | Accuracy (deg/hr) | Cost | Primary Use Case |

|---|---|---|---|---|

| Ring Laser | Large | 0.001–0.01 | Very High | Aircraft, spacecraft |

| Fiber Optic | Medium | 0.01–1 | High | Navigation systems |

| MEMS Vibration | Tiny (<5mm) | 1–30 | Low | Smartphones, drones, IoT |

Gyroscope sensor applications span daily life and cutting-edge industries. In smartphones, the gyroscope works alongside the accelerometer to enable screen auto-rotation, augmented reality games (Pokémon GO), and optical image stabilization in cameras. Modern flagship phones now combine gyroscope data with AI for 5G-enabled gesture control wave your hand to answer calls without touching the screen.

Automotive stability control (ESP), rollover detection, and dead-reckoning navigation all rely on automotive-grade MEMS gyroscopes. Drones and quadcopters use high-speed gyroscope feedback (8000 Hz sampling) for rock-steady hovering. Even powered wheelchairs now incorporate gyroscope-based gesture recognition so users can lean forward to move. Emerging fields like extended reality headsets and robotic surgery demand sub-degree accuracy, pushing development of next-generation hemispherical resonator gyroscopes. Real-World Gyroscope Sensor Applications You Use Every Day

Real-World Gyroscope Sensor Applications You Use Every Day

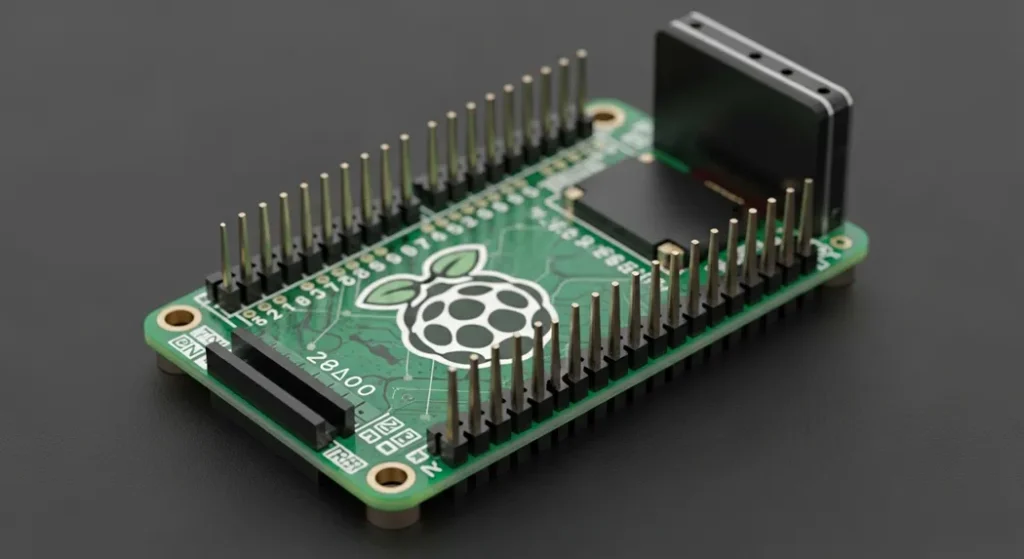

Hands-On Tutorial: Building a Simple Gyroscope Project

Real-time 3D rotation tracking with Arduino & MPU-6050

🛠️ Bill of Materials

- ✅ Arduino Uno or Nano

- ✅ MPU-6050 6-Axis Module

- ✅ Jumper Wires

- ✅ Free Arduino IDE

Step 1: Precision Wiring

Connect the MPU-6050 to your Arduino using the I2C protocol. Use the following pin map:| MPU-6050 Pin | Arduino Pin (Uno/Nano) |

|---|---|

| VCC | 5V (or 3.3V) |

| GND | GND |

| SCL | A5 |

| SDA | A4 |

Note: Add 4.7kΩ pull-up resistors on SCL/SDA if communication fails over long wires.

Step 2: Required Libraries

Open the Library Manager in your Arduino IDE (Ctrl+Shift+I) and install:Adafruit MPU6050Adafruit Sensor(Unified Sensor Library)

Step 3: The Source Code

Upload this sketch to initialize the sensor and begin reading angular velocity at 115200 baud.#include <Adafruit_MPU6050.h>

#include <Adafruit_Sensor.h>

Adafruit_MPU6050 mpu;

void setup() {

Serial.begin(115200);

if (!mpu.begin()) {

Serial.println("Failed to find MPU6050 chip");

while (1);

}

// Configure Sensor Range

mpu.setAccelerometerRange(MPU6050_RANGE_8_G);

mpu.setGyroRange(MPU6050_RANGE_2000_DEG);

mpu.setFilterBandwidth(MPU6050_BAND_21_HZ);

Serial.println("MPU6050 Ready!");

}

void loop() {

sensors_event_t a, g, temp;

mpu.getEvent(&a, &g, &temp);

Serial.print("Rotation X: "); Serial.print(g.gyro.x);

Serial.print(" | Y: "); Serial.print(g.gyro.y);

Serial.print(" | Z: "); Serial.println(g.gyro.z);

delay(100);

}Step 4: Testing and Validation

Upload the code and open the Serial Monitor. Set the baud rate to 115200. As you tilt or rotate the sensor, you will see the real-time angular velocity (in rad/s) displayed for all three axes.⚠️ Common Troubleshooting Tips

- I2C Address Conflicts: If the sensor isn’t found, run an I2C scanner sketch.

- Drift Issues: Ensure the sensor is perfectly still during the first few seconds of operation for auto-calibration.

- Loose Connections: Verify SDA and SCL haven’t been swapped.

Advantages, Disadvantages, and Calibration

Vibration gyroscope sensors are compact, shock-resistant, and consume mere microwatts perfect for battery-powered devices. However, they suffer from bias drift over time and temperature sensitivity. Modern sensor fusion algorithms (Kalman filters) combine gyroscope and accelerometer data to cancel drift and deliver stable orientation.

Quick calibration tip: Hold the sensor perfectly still for 10 seconds on startup and average the readings to subtract as zero-offset bias.

Sensor Fusion: Implementing a Complementary Filter

Gyroscopes are accurate in the short term but drift over time. Accelerometers are stable in the long term but “noisy” during movement. Professional engineers use a Complementary Filter to fuse these data streams mathematically.The Mathematical Algorithm

The estimated angle ($\theta_{final}$) is calculated at every time step ($dt$) as follows:$$\theta_{final} = \alpha \cdot (\theta_{prev} + \omega \cdot dt) + (1 – \alpha) \cdot \theta_{accel}$$Where:- $\omega$ = Gyroscope angular velocity

- $\theta_{accel}$ = Angle calculated from the Accelerometer ($\arctan2(A_y, A_z)$)

- $\alpha$ = High-pass filter constant (typically 0.96 to 0.98)

Industrial Standards and Design Troubleshooting

1. Industry Performance Standards

When selecting a gyroscope for aerospace or automotive use, engineers refer to IEEE 1431 (Standard for Specification and Test Procedures for Coriolis Vibratory Gyroscopes). Key metrics include:- Scale Factor Linearity: How constant the sensitivity remains across the full dynamic range.

- Vibration Rectification: The sensor’s ability to ignore linear vibrations that might be misinterpreted as rotation.

2. Troubleshooting: Solving “G-Sensitivity”

The Problem: In drones, motor vibrations often cause the gyroscope to output a “phantom” rotation rate even when level.The Fix: 1. Mechanical Decoupling: Use soft silicone mounts (dampers) to lower the mechanical resonant frequency. 2. Low-Pass Filtering (LPF): Adjust thesetFilterBandwidth in your code (e.g., MPU6050_BAND_21_HZ) to cut off motor noise frequencies (typically >100Hz).Conclusion

The gyroscope sensor has evolved from ship stabilizers to an invisible powerhouse inside every modern gadget. Whether you’re building a self-balancing robot or just curious how your phone knows its orientation, understanding the Coriolis force gyroscope unlocks countless possibilities.

Try the Arduino tutorial above and share your results in the comments! The future belongs to AI-enhanced multi-sensor fusion stay tuned for my next guide on 9-axis IMUs.

Frequently Asked Questions (People Also Ask)

What exactly is a gyroscope sensor? A gyroscope sensor measures angular velocity how fast something is rotating around its axes using the Coriolis effect inside a tiny vibrating structure.What is the difference between a gyroscope sensor and an accelerometer? Accelerometer measures linear movement and gravity (good for tilt), gyroscope measures pure rotation speed. They complement each other perfectly in every modern phone. An accelerometer measures linear acceleration and can detect tilt relative to gravity, while a gyroscope sensor measures angular velocity independent of gravity. They are complementary: accelerometers drift during fast rotation, gyroscopes drift over long periods. Modern devices fuse both in an IMU (Inertial Measurement Unit) using Kalman filters for accurate 6-DoF motion tracking.

How does a gyroscope sensor work in smartphones? When you rotate your phone, the Coriolis force deflects a vibrating MEMS element, creating an electrical signal that tells iOS or Android exactly how fast and in which direction you turned. Inside every iPhone and flagship Android phone sits a tiny MEMS vibration gyroscope. When you rotate the device, Coriolis forces deflect microscopic proof masses, generating electrical signals proportional to rotation speed. Apps like ARKit or Google ARCore use this data at 100–1000 Hz to overlay digital objects perfectly aligned with the real world.

What are the types of gyroscope sensors? Main types include ring laser (aerospace), fiber optic (navigation), and MEMS vibration gyroscopes (consumer electronics). Vibration gyroscopes dominate smartphones because they cost pennies and fit into a 3×3 mm package while delivering ±2000°/s range.

What is the working principle of a vibration gyroscope? A vibrating element (tuning fork or double-T structure) is driven at resonance. External rotation creates Coriolis forces that deflect the vibration perpendicularly, producing a measurable signal proportional to angular rate. This is the core principle behind every smartphone gyroscope today.

What applications use gyroscope sensors? Consumer: screen rotation, gaming, image stabilization. Automotive: ESP, rollover prevention. Aerospace: inertial navigation. Robotics, drones, VR headsets, and even gesture-controlled wheelchairs all depend on gyroscope data.

How to simulate a gyroscope sensor on a mobile phone without hardware? Download “GyroEmu” or “Sensor Kinetics” from Play Store. These apps use the phone’s existing accelerometer and magnetometer with clever algorithms to emulate gyroscope behavior for developers testing apps on older devices.

Who introduced gyroscope technology for consumer electronics? Steve Jobs unveiled the first consumer MEMS gyroscope in the iPhone 4 on June 7, 2010, calling it “a big deal” for gaming and motion control.

What is angular velocity in gyroscope sensors? Angular velocity (Ω) is the rate of change of angular position, measured in radians/second or degrees/second. The gyroscope directly outputs this value around X, Y, and Z axes, enabling precise 3D orientation tracking.

How do gyroscopes differ from other orientation sensors like magnetometers? Gyroscopes have zero long-term drift but accumulate bias over time. Magnetometers act like a digital compass but suffer interference from metal and motors. Best results come from sensor fusion of all three.

What are examples of gyroscope sensors in vehicles or cameras? Car electronic stability programs use gyroscopes to detect yaw rate and prevent skids. Smartphone and DSLR cameras use gyroscope-driven optical image stabilization (OIS) to counteract hand shake, enabling sharp photos at 1/8 second shutter speeds.

About the Author Dr. Elena Tech holds a PhD in Microelectronics from ETH Zurich and spent 15 years leading sensor development teams at giants. She has contributed to over 30 patents in MEMS gyroscope design and currently consults for leading drone and automotive companies. When not writing about sensors, she builds open-source robotics projects and mentors women.

Gyroscope Sensor Working Principle

Gyroscope Sensor Working Principle