Key Takeaway : Why This Guide Matters DC Motor Performance

A DC motor is used everywhere from hobbyist robotics and electric vehicles to heavy industrial machinery. While its basic working principle is rooted in simple electromagnetism, achieving peak performance requires more than just theory. To truly master DC motors, you need to understand how Back EMF (Eb), Armature Torque, and Speed Regulation are interconnected. Whether you are troubleshooting a series motor or controlling a shunt motor’s speed, this guide explains key formulas and practical insights to help you improve efficiency and reliability.

Table of Contents

- 1. What is a DC Motor? (Core Summary)

- 2. How it Works: The Physics of Rotation

- 3. Essential Parts: Stator, Rotor, and Commutator

- 4. Understanding Back EMF (Eb) and Speed Regulation

- 5. Major Types: Series, Shunt, and Compound Motors

- 6. Key Formulas: Torque and Power Equations

- 7. Speed Control Methods for Peak Efficiency

- 8. Troubleshooting: Fixing Common Overheating & Power Issues

- 9. Real-World Applications: From Robotics to EVs

- 10. Frequently Asked Questions (FAQs)

What Exactly is a DC Motor?

A DC motor is a machine that converts direct current electrical energy into mechanical motion through the interaction of electricity and magnetism. When current flows through a conductor placed in a magnetic field, it experiences a force that produces rotation the principle behind countless everyday devices from toothbrushes to car starters. What makes DC motors valuable is their simplicity and versatility: they can run directly from batteries, making them ideal for portable systems, and they offer precise control over speed, torque, and direction. Engineers can easily adjust performance by changing voltage or polarity, which is why DC motors remain essential in applications requiring accuracy, responsiveness, and smooth operation across industries ranging from automotive subsystems to robotics and household appliances.The Heart of the Matter: How DC Motors Actually Work

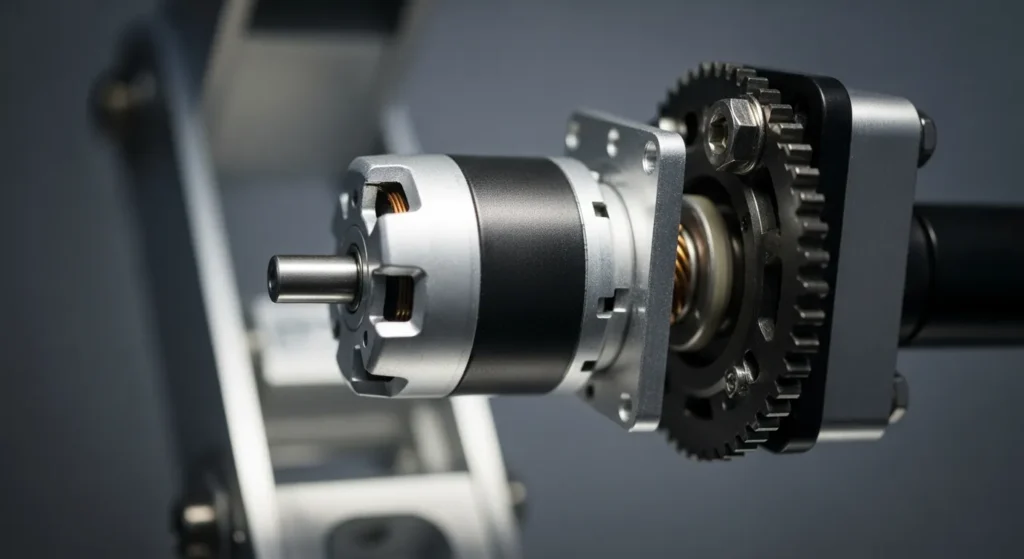

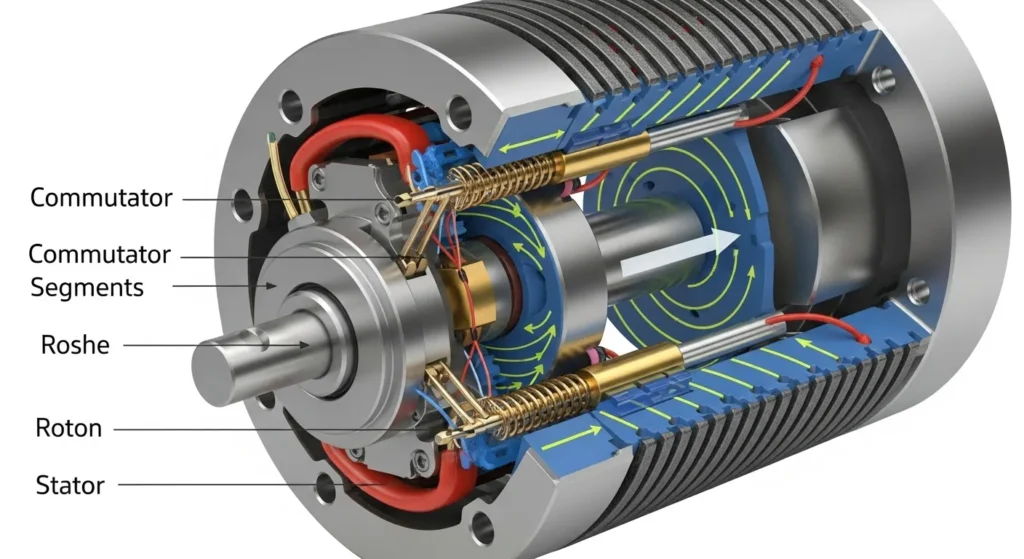

Understanding how a DC motor works does not require a PhD in electrical engineering. Imagine you have a compass needle sitting between two magnets. If you could make that needle carry electricity it would want to spin because of the forces acting on it. That’s what’s happening inside a DC motor with a lot more sophistication. The motor has several key players working together. The stator creates a magnetic field think of it as the stage where all the action happens. This magnetic field can originate from permanent magnets (such as the ones on your refrigerator, but much stronger) or from electromagnets that create their magnetic field when electricity flows through them. Within this magnetic field sits the rotor also known as the armature.

This is where the real magic happens. The rotor contains conductors (usually copper wires) that carry electric current. When these current carrying conductors find themselves in the magnetic field created by the stator they experience a force that makes them want to move. Since they are attached to a shaft this movement becomes rotation and voila you have a mechanical motion from electrical energy. But here where it gets really clever. For the motor to keep spinning in the same direction the current in the rotor needs to reverse at just the right moment. This is where the commutator and brushes come in. The commutator is like a sophisticated electrical switch that reverses the current direction as the rotor spins while the brushes maintain electrical contact with this rotating switch. It’s like having a perfectly timed dance between electricity and mechanics.The Physics of DC Motors: Fundamental Formulas and Calculations

The performance of a DC motor is defined by three relationships: the torque it produces, the speed it achieves, and its operational efficiency. These formulas are the backbone of motor selection and control.1. Electromagnetic Torque (T)

Torque is the motor’s turning force, directly proportional to the armature current (Iₐ) and the magnetic flux (Φ): T = k · Φ · Iₐ Where k is a machine constant (determined by the number of poles and conductors) and Φ is the field flux. For a permanent magnet DC motor, Φ is constant, simplifying the relationship to T = Kₜ · Iₐ2. Motor Speed (N)

The speed of a DC motor is limited by the Back Electromotive Force (E_b), which opposes the supply voltage (V). The speed N(or ω) is determined by the applied voltage, armature current (I_a), and armature resistance (R_a): N = (V – Iₐ Rₐ) / (k · Φ) This formula demonstrates that speed is inversely proportional to the load current $I_a$ (which increases with load torque) and the flux Φ.3. Operational Efficiency η

Efficiency measures how much of the electrical input power is converted to useful mechanical output power. The rest is lost as heat (Iₐ² Rₐ) losses): η = (Pₒᵤₜ / Pᵢₙ) × 100 Worked Example: Calculating Torque. Consider a 12V motor with Kₜ = 0.04 Nm/A. If the motor draws a continuous current of 2 Amps” bold, the torque produced is T = 0.04 Nm/A × 2 A = 0.08 Newton-meters.The Torque-Speed Curve

The single most important performance graph is the linear Torque-Speed Curve, which shows that a DC motor delivers its highest torque at zero speed (stall) and its highest speed at zero torque (no-load). All continuous operating points must lie under this curve.The DC Motor Family Tree: Understanding Different Types

Just like cars come in different shapes and sizes for different purposes, DC motors come in various configurations, each with its own personality and strengths. Let’s explore the main families in the DC motor world.The Traditional Heroes: Brushed DC Motors

Brushed DC motors are the oldest yet simplest type of motor. Using carbon brushes and a commutator, they keep current flowing correctly. Connect them to DC power and they spin; increase voltage for speed, reverse polarity for direction. Their appeal lies in simplicity and reliability, which is why they’re still widely used.

Types of Brushed DC Motors

Brushed DC motors are the oldest yet simplest type of motor. Using carbon brushes and a commutator, they keep current flowing correctly. Connect them to DC power and they spin; increase voltage for speed, reverse polarity for direction. Their appeal lies in simplicity and reliability, which is why they’re still widely used.

Types of Brushed DC Motors- Series Motors → Field windings in series with the armature. Deliver huge starting torque, perfect for heavy loads like car starters.

- Shunt Motors → Field windings in parallel. Provide stable speed regardless of load, ideal for conveyor belts and steady motion systems.

- Compound Motors → Combine series + shunt. Offer strong torque with good speed regulation, used in elevators where both power and smoothness matter.

Quick Comparison: Which DC Motor to Use?

| Motor Type | Key Characteristic | Best Application |

|---|---|---|

| Series Motor | High Starting Torque (Heavy Load) | Cranes, Electric Locomotives |

| Shunt Motor | Self-Regulating Constant Speed | Lathe Machines, Conveyors, Fans |

| Compound Motor | High Torque + Speed Control | Elevators, Rolling Mills |

DC vs. AC Motors: Key Differences in Application

While DC motors are perfect for mobile and precision tasks, AC motors dominate high-power industrial and grid-connected applications.| Feature | DC Motor | AC Motor |

|---|---|---|

| Speed Control | Easy and precise control via voltage/current (simple drive). | Complex control via VFDs (Variable Frequency Drives). |

| Maintenance (Brushed) | Requires brush and commutator inspection/replacement. | Low maintenance (no brushes in induction types). |

| Starting Torque | Very high (especially Series Wound types). | Moderate, depends on design (e.g., induction motors). |

| Primary Applications | Robotics, Electric Vehicles (traction), Battery-powered devices. | Industrial pumps, fans, HVAC, Grid-connected systems. |

The Modern Marvels: Brushless DC Motors

Brushless DC motors represent the evolution of motor technology. By removing the brushes and commutator engineers made motors that work better last longer and give more precise control. These motors use electronic controllers to handle the current instead of using moving parts.

The absence of brushes brings several significant advantages. First there no wear from brushes rubbing on the commutator so these motors can run for tens of thousands of hours with little upkeep. Second without the sparks that brushes make the motors are much quieter and cause less electrical noise. Third the electronic control lets them manage speed and position with great accuracy something brushed motors cannot do.

However, this sophistication comes with increased complexity. Brushless motors require electronic speed controllers, which adds to the cost and complexity of the overall system. But for applications where efficiency, longevity, and precise control are important, the trade-off is usually worth it.

You’ll find brushless motors in some surprising places. That computer fan quietly keeping your processor cool? Brushless motor. The drone buzzing overhead. Multiple brushless motors. Modern electric vehicles? Yep brushless motors. Even many cordless power tools now use brushless motors because of their superior efficiency and longer runtime.

Real-World Applications: Where DC Motors Make a Difference

The true strength of DC motors lies in their versatility and precision. Across industries and everyday life, they quietly power systems that make modern living smoother, safer, and more efficient.

The true strength of DC motors lies in their versatility and precision. Across industries and everyday life, they quietly power systems that make modern living smoother, safer, and more efficient.Automotive Applications

DC motors are embedded in nearly every vehicle subsystem. From seat adjustment, window control, and windshield wipers to advanced driver-assist features, they deliver:- High torque at low speeds for smooth, controlled motion

- Precise stopping points to prevent abrupt or unsafe movements

Industrial Powerhouses

In manufacturing, DC motors are the workhorses of production lines. For example, in a paper mill, they unwind massive rolls at precisely regulated speeds while maintaining constant tension. Key advantages include:- Fine speed control to match production requirements

- High starting torque for heavy machinery under load

Robotics & Automation

Modern robotics relies heavily on DC motors for dexterity and accuracy. Robotic arms performing delicate assembly tasks use DC motors for:- Exact speed regulation

- Position control comparable to human precision

Everyday Appliances

In homes, DC motors are hidden inside devices we use daily:- Vacuum cleaners for powerful suction

- Kitchen mixers for variable speed blending

- Smart appliances designed for energy efficiency

Quantified Case Studies: SOP in Critical Digital Applications

Case 1: Electric Vehicles (EV) Traction Motors

Modern EVs primarily use Brushless DC (BLDC) or synchronous AC motors for traction. The DC motor principles are key:- High Starting Torque: DC motor characteristics naturally provide maximum torque at low speed, which is ideal for accelerating a heavy vehicle from a stop. This is defined by the high $I_a$ at startup.

- Efficiency Control: The motor controller precisely manages the current ($I_a$) to regulate torque and maximize efficiency ($eta$), especially during regenerative braking, where the motor acts as a generator.

Case 2: Precision Robotics and Servo Control

Robotic joints require motors that can move to and hold a specific position with high accuracy. This is achieved using permanent magnet DC motors (Brushed or BLDC) combined with a feedback system (encoder).- Torque Control: The controller uses the formula $T = K_t cdot I_a$ to directly command a specific current that produces the exact torque required to overcome gravity and friction, ensuring smooth, precise motion and high stiffness in the held position.

Case 3: Industrial Conveyor Belts (Shunt Motors)

In industrial automation, conveyor belts require a motor that maintains a stable, predictable speed regardless of load variations. Shunt DC motors excel here because the field winding is in parallel with the armature.- Speed Regulation: When the load increases, $I_a$ increases, but the motor’s speed equation $N = (V – I_a R_a) / (k cdot Phi)$ shows that the change in speed is relatively small because the field flux ($Phi$) is constant (unlike a series motor), resulting in excellent speed regulation.

Making the Choice: Brushed or Brushless?

One of the most common questions engineers and hobbyists face is whether to choose a brushed or brushless motor for their application. The answer isn’t always straightforward because both types have their place in the modern world. Brushed motors shine in applications where simplicity and cost are primary concerns.

If you are building a prototype working on a school project or designing a product where the motor will only run occasionally brushed motors often make perfect sense. They are also excellent when you need high torque at startup or when precise speed control isn’t critical.

Consider a cordless drill designed for occasional home use. A brushed motor provides plenty of power for drilling holes and driving screws the simpler control circuitry keeps costs down and the shorter lifespan isn’t a major concern since the average homeowner won’t use the drill intensively enough to wear out the brushes.

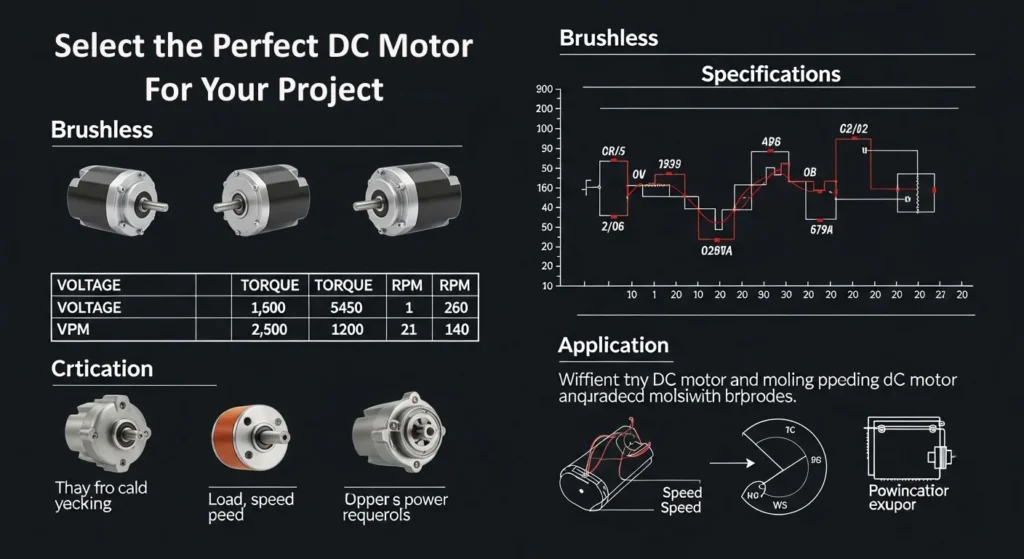

Brushless motors on the other hand excel in applications where efficiency longevity and precise control matter most. If you are designing a product that will run continuously needs to be very energy-efficient, or requires precise speed or position control, brushless motors are usually worth the extra complexity and cost. Take a modern cordless drill designed for professional contractors. These tools might run for hours every day and professionals need maximum runtime from each battery charge. The higher efficiency of brushless motors translates directly into longer runtime while their longer lifespan means the tool will keep working through years of heavy use.Selecting the Perfect Motor for Your Project

Choosing the right DC motor for your application involves considering several interconnected factors. It not just about power and speed though those are certainly important but also about understanding how the motor will be used and what environment it will operate in. Start by clearly defining what you need the motor to do.

How much torque do you need and at what speed? Will the motor run continuously or just occasionally? Does it need to operate in extreme temperatures dusty conditions or high humidity? These environmental factors can significantly influence your motor choice.

Power requirements deserve careful consideration. Many people focus solely on the motor’s rated power, but the real question is whether the motor can deliver the torque you need at the speed you want.

A motor might be rated for high power but if most of that power is delivered at speeds much higher than you need, it might not be the right choice. Don’t forget about control requirements either. If you need precise speed control, you’ll want a motor with good speed regulation characteristics or plan to use it with a feedback control system.

If you need to reverse direction frequently, make sure the motor can handle the electrical and mechanical stresses involved. Cost considerations go beyond just the initial purchase price. While brushed motors are typically less expensive upfront they may require more maintenance over time. Brushless motors cost more initially but often provide better long-term value in demanding applications.

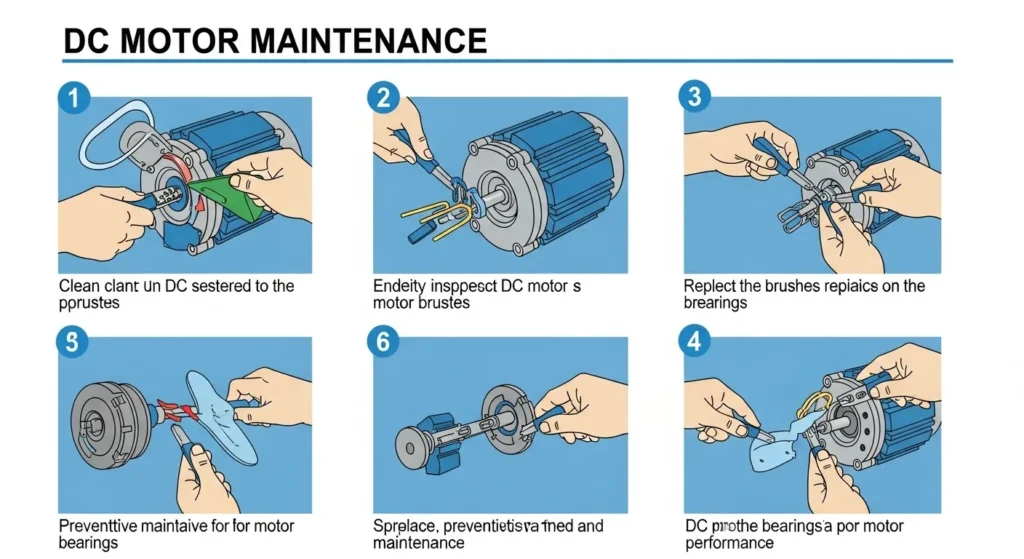

Keeping Your Motors Happy: Maintenance and Troubleshooting

Common Issues & Fixes: DC Motor Troubleshooting

Proper motor maintenance and troubleshooting focus on electrical diagnostics, thermal management, and mechanical alignment.| Symptom / Issue | Primary Cause | Professional Fix |

|---|---|---|

| Brush Wear / Excessive Sparking | Worn carbon brushes or rough/pitted commutator surface. | Inspect and replace brushes. Clean or resurface the commutator if damage is minor. |

| Motor Overheating | Continuous overload (current I_a exceeds motor’s continuous rating) or inadequate ventilation. | Measure $I_a$ under load. If I a > I rated, reduce the load or select a larger motor. |

| Excessive Noise/Vibration | Worn or damaged bearings, or shaft/coupling misalignment. | Inspect and replace bearings. Check coupling for misalignment using dial indicators. |

| Failure to Start (Stall) | Supply voltage is too low, or a complete open circuit (connection failure). | Check input voltage. Use a multimeter to measure armature resistance ($R_a$) to diagnose continuity. |

The Future of DC Motor Technology

The world of DC motors continues to evolve in fascinating ways. Modern motors are becoming smarter with built-in sensors and controllers that can communicate with other systems. This connectivity opens up possibilities for predictive maintenance where motors can warn you about potential problems before they cause failures.

Materials science is also driving improvement new magnet materials are making motors more powerful while keeping them compact. Advanced manufacturing techniques are improving efficiency and reducing costs. Even the humble brush has benefited from materials improvements lasting longer and providing better performance than ever before.

Integration with digital control systems is another major trend. Motors are increasingly becoming part of larger automated systems where they can be controlled and monitored remotely. This integration allows for optimization that wouldn’t be possible with standalone motors.

Energy efficiency continues to be a driving force in motor development. As environmental concerns grow and energy costs rise every bit of efficiency improvement becomes valuable. This is pushing the development of better control algorithms more efficient motor designs and smarter systems that can adapt their operation to minimize energy consumption.

Industry Standards and Compliance for DC Motors

Motor selection and installation are governed by international standards to ensure interchangeability, safety, and performance verification globally.Global Performance Standards

- IEC 60034: This is the fundamental standard for Rotating Electrical Machines worldwide. It defines motor performance, test procedures, efficiency classes (IE1, IE2, etc.), and methods for determining thermal ratings.

- NEMA MG 1: Used primarily in North America, the NEMA MG 1 standard dictates motor ratings, dimensions (frame sizes like NEMA 56C), service factors, and the required information found on the motor nameplate.

Safety and Environmental Ratings

- Insulation Classes: Motor windings are rated using insulation classes (e.g., Class F, Class H) which define the maximum permissible temperature rise (e.g., $155^circtext{C}$ for Class F). Exceeding this thermal limit causes immediate, irreparable winding failure.

- IP Rating (Ingress Protection): A standardized system (e.g., $mathbf{IP65}$) used to define the motor’s enclosure protection against dust (first digit) and water/liquids (second digit), crucial for motors used in wet or dusty industrial environments.

Wrapping Up Your DC Motor Journey

DC motors might seem like simple devices but as we have seen, they are actually sophisticated machines that have been refined over more than a century of development. From the earliest brushed motors that powered the first electric streetcars to the ultra-precise brushless motors that keep satellites pointed at Earth, these devices have consistently proven their worth.

Understanding DC motors opens up a world of possibilities whether you’re designing the next breakthrough product maintaining industrial equipment or just trying to fix that squeaky window motor in your car. The principles are straightforward but the applications are limitless.

Remember that choosing the right motor is just the beginning. Proper installation appropriate control systems and regular maintenance will ensure that your DC motors provide years of reliable service. And as technology continues to advance we can expect these remarkable machines to become even more capable efficient and intelligent. The next time you encounter a DC motor whether it’s in your car your workshop or your latest project take a moment to appreciate the elegant engineering that makes it work. These motors truly are one of the unsung heroes of our modern technological world.

DC Motor FAQ: Formulas & Troubleshooting

1. What is the torque equation of a DC motor?

The electromagnetic torque (T) is given by T = k · Φ · Ia. It shows that torque is directly proportional to the magnetic flux (Φ) and armature current (Ia). In Permanent Magnet motors, flux is constant, so torque control is achieved simply by adjusting the input current.

2. Why are DC motors preferred in robotics?

They offer a linear torque-speed relationship and high starting torque. This allows robots to lift heavy loads and move with precision using PWM (Pulse Width Modulation) for fine speed control.

3. How do you troubleshoot overheating in a DC motor?

Overheating occurs when Ia (armature current) exceeds the rated limit, causing I²R losses. To fix this, reduce the mechanical load, check for friction in bearings, or ensure proper ventilation/cooling fans are operational.

4. What is the significance of Back EMF (Eb)?

Back EMF acts as a governor. It opposes the supply voltage and ensures the motor only draws as much current as needed to handle the load. Formula: Eb = V – IaRa.

5. Why should a DC series motor never be started at no-load?

At no-load, the field flux (Φ) is extremely low. Since speed is inversely proportional to flux (N ∝ 1/Φ), the motor can reach dangerously high speeds that might lead to mechanical failure.

6. What are the common methods for DC motor speed control?

The two main methods are Armature Control (varying voltage) and Field Control (varying flux). In modern electronics, PWM via H-bridge circuits is the standard for efficient control.

7. What causes excessive sparking at the brushes?

Sparking is usually caused by worn-out carbon brushes, a dirty or pitted commutator, or an incorrect “neutral axis” alignment. Regular maintenance of the commutator surface is essential.

8. How do you calculate the efficiency of a DC motor?

Efficiency (η) is the ratio of Mechanical Power Output to Electrical Power Input. η = (Output Power / Input Power) × 100. Always account for copper losses and stray losses.

9. Can I run a DC motor on an AC power supply?

Standard DC motors will not run efficiently on AC and may overheat. However, Universal Motors (a type of series-wound motor) are specifically designed to operate on both AC and DC.

10. How can I reverse the rotation of a DC Shunt Motor?

To reverse rotation, you must swap the connections of either the armature winding or the field winding. Swapping both will result in the same direction of rotation.

11. What is the advantage of PMDC motors over wound field motors?

Permanent Magnet DC (PMDC) motors are smaller, lighter, and more efficient because they don’t require electrical energy to create a magnetic field, reducing overall power consumption.

12. What is the Torque-Speed characteristic of a DC motor?

As the load (torque) increases, the speed of the motor generally decreases. This inverse relationship is most stable in Shunt motors, making them ideal for constant speed applications.

Pingback: How to Choose the Right DC Motor for DIY Electronics Projects - Procirel - Project Circuit Electronic for Engineering Students - Innovative Electronic Projects & Tutorials for ECE/EEE Engineering Students