Key Takeaway: A full-wave rectifier is a critical electronic component that converts alternating current (AC) to direct current (DC) by efficiently utilizing both halves of the AC waveform. Unlike half-wave rectifiers, this system doubles the output frequency and significantly reduces ripple voltage to 0.48, resulting in a much smoother and more stable DC supply. Modern designs, including bridge and center-tapped circuits, achieve an impressive theoretical efficiency of 81.2%, making them indispensable for power supplies, battery chargers, and industrial motors. By adhering to international standards such as IEC 60146, these rectifiers ensure high voltage regulation and reliability, providing a high-performance solution for both consumer electronics and heavy-duty industrial applications.

Table of Contents

- Introduction to Full Wave Rectifiers

- What is a Full Wave Rectifier?

- Working Principle of Full Wave Rectification

- Key Circuit Types

- Technical Calculations & Formulas

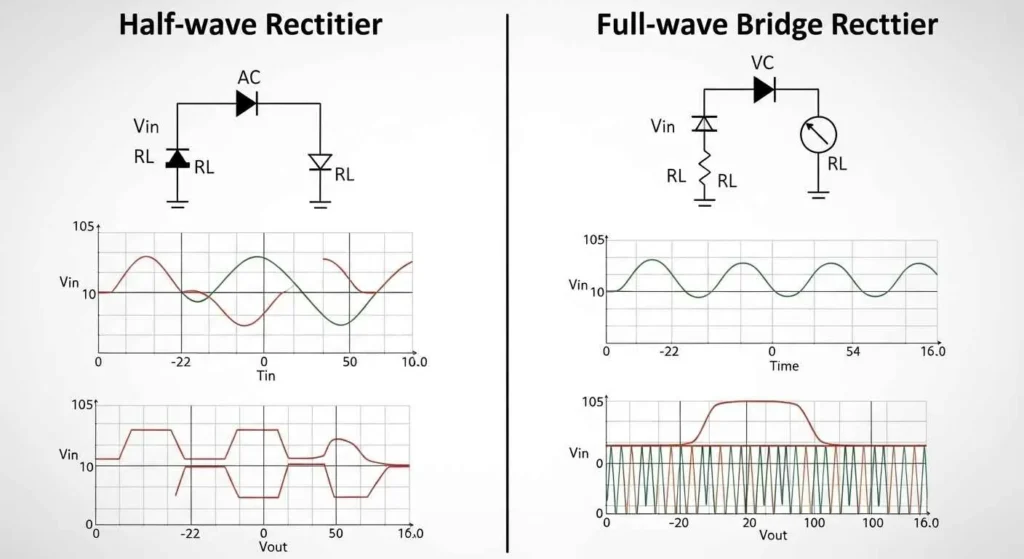

- Full Wave vs. Half Wave Rectifier Comparison

- Advantages of Full Wave Rectification

- Real-World Applications in Electronics

- Design Standards & Industry Compliance (IEC/IEEE)

- Frequently Asked Questions (FAQs)

Introduction to Full Wave Rectifiers

In the world of electronics, converting alternating current to direct current is a fundamental process that powers countless devices, from simple chargers to complex systems. A full wave rectifier stands out as a key component in this conversion, efficiently utilizing both halves of the AC waveform to produce a smoother DC output. This guide dives deep into the full wave rectifier, explaining its principles, circuits, and real-world uses in a way that’s accessible yet detailed. Whether you’re a student exploring AC to DC conversion or an engineer seeking insights on rectifier efficiency and ripple factor, you’ll find comprehensive explanations here, including practical calculations and comparisons with half wave rectifiers. By understanding the full wave rectifier circuit, including types like the center tapped full wave rectifier and bridge rectifier, you’ll grasp how it enhances voltage regulation in DC power supplies. This article goes beyond basics, offering actionable advice on building and testing these circuits, ensuring you can apply the knowledge directly. Discover why full wave rectifiers are essential in modern electronics, outperforming simpler alternatives in efficiency and output quality.

What is a Full Wave Rectifier?

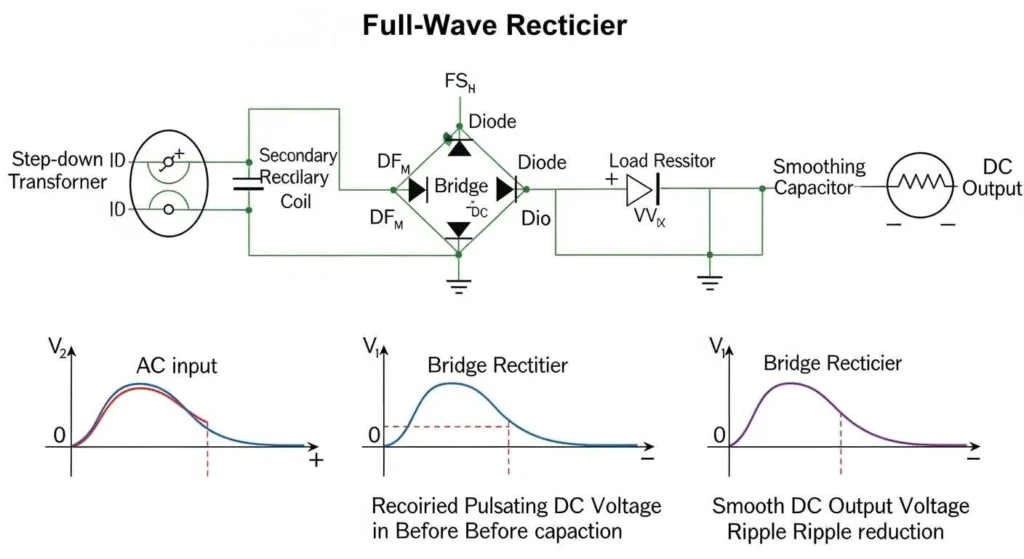

A full wave rectifier is an electronic circuit designed to convert the entire AC input signal into a pulsating DC output, making it a vital AC to DC converter. Unlike simpler designs, it processes both the positive and negative halves of the AC cycle, resulting in a more consistent DC power source. This capability makes it ideal for applications requiring stable direct current power supply, such as in power DC supply systems where voltage regulation is crucial.

The core function involves diodes that direct current flow, ensuring the output remains unidirectional. In contexts like DC voltage converter setups, this rectifier type integrates well with components like zener diodes for enhanced voltage regulation. For instance, when paired with a DC power supply module, it supports efficient energy transfer, minimizing waste.

Experts often highlight its role in switch mode power supply designs, where it handles AC 12V inputs effectively. The rectifier’s ability to produce DC powered outputs positions it as a cornerstone in electronics, surpassing basic half bridge configurations in performance.

Full Wave Rectifier Definition

Defining a full wave rectifier involves recognizing it as a device that rectifies both halves of an AC waveform into DC, providing a higher average output voltage. This full wave rectifier definition underscores its superiority in AC to DC voltage converter applications, where consistent DC supply power is needed.

In detailed circuit property explanations, the full wave rectifier stands out for its use of diode bridges or center taps, enabling seamless conversion. When integrated with a silicon controlled rectifier for controlled rectification, it enhances precision in power management.

Such definitions often link to foundational concepts, emphasizing how it serves as a reliable DC power source in various setups.

Types of Full Wave Rectifiers

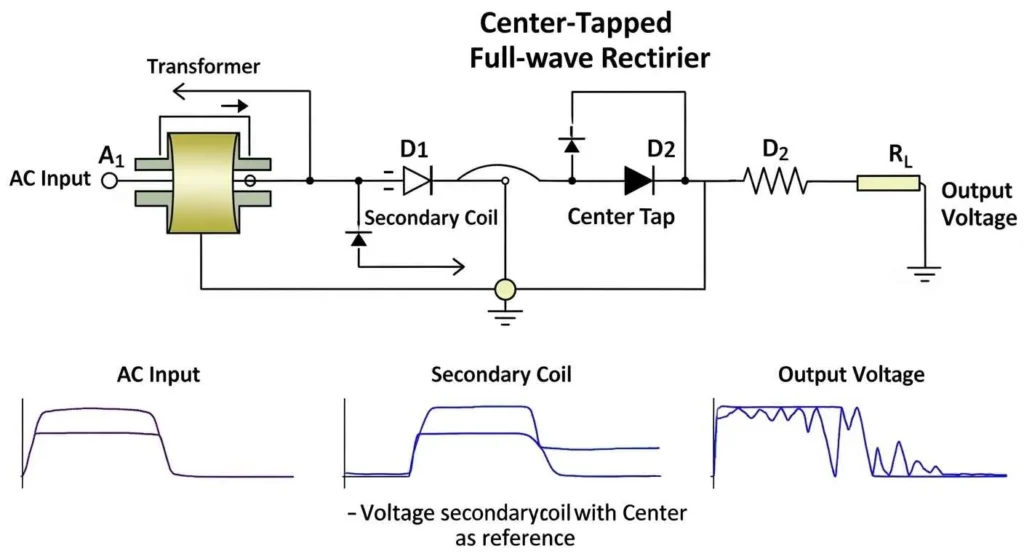

Full wave rectifiers come in primary configurations, each suited to specific needs in electronics. The center tapped full wave rectifier uses a transformer with a center tap, employing two diodes to handle each half cycle, ideal for balanced loads.

Alternatively, the bridge rectifier, also known as diode bridge rectifier, utilizes four diodes in a bridge formation, eliminating the need for a center tap and offering robustness in high-power scenarios.

Both types excel in converting AC to DC, with the diode bridge often preferred for its simplicity in DC to DC voltage converter integrations.

Center Tapped Full Wave Rectifier

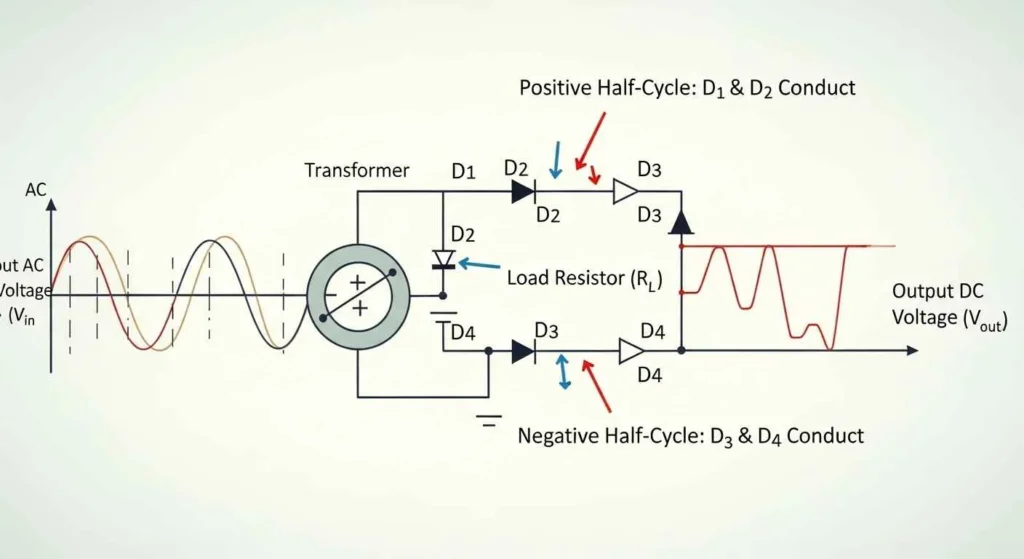

The center tapped full wave rectifier employs a transformer with a center-tapped secondary winding and two diodes. During the positive half cycle, one diode conducts while the other blocks, directing current through the load. In the negative half cycle, the roles reverse, ensuring continuous DC flow.

This configuration provides insights on diode configurations, making it suitable for applications requiring stable voltage, such as in buck converter systems where voltage regulation follows rectification.

Practical implementations often include schottky diodes for lower forward voltage drops, enhancing efficiency in DC power setups.

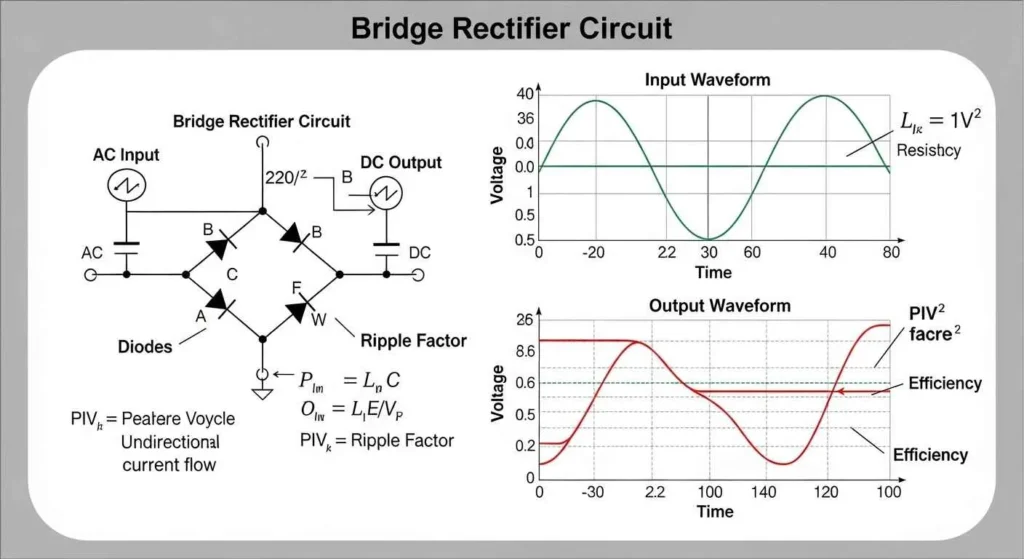

Bridge Rectifier

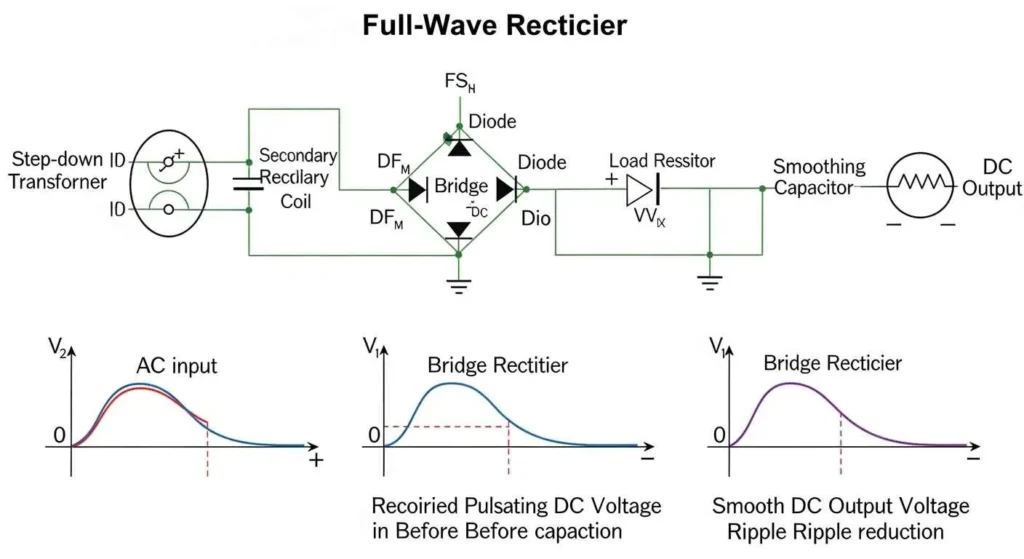

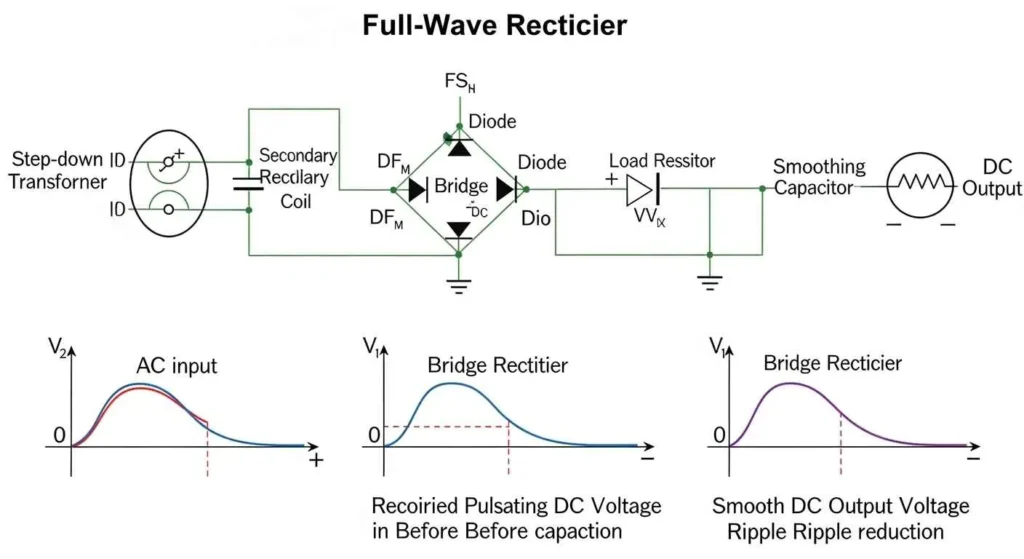

A bridge rectifier consists of four diodes arranged in a closed loop, converting AC to DC without a center-tapped transformer. It allows current to flow through the load in the same direction during both half cycles, producing a pulsating DC output.

This design serves as a comprehensive rectifier type resource, commonly used in power supply for testing environments due to its reliability.

Incorporating elements like photo diodes in sensing applications alongside the bridge can expand functionality, though primarily it’s for core rectification.

How Does a Full Wave Rectifier Work?

The operation of a full wave rectifier begins with an AC input applied to the diodes. In a bridge setup, two diodes conduct during the positive half, routing current to the load, while the other two handle the negative half, maintaining unidirectional flow.

This process minimizes ripple, aiding in electronics and circuit behavior analysis. For smoother outputs, capacitors are added, filtering the DC power. In systems involving half bridge topologies, the full wave approach offers better performance, especially when combined with DC voltage converter modules.

Full Wave Rectifier Circuit

Constructing a full wave rectifier circuit involves connecting diodes strategically to handle AC phases. For a bridge version, diodes form a diamond shape, with AC input at opposite points and DC output at the others. This circuit excels in circuit-related electronics applications, often incorporating zener diodes for voltage clamping.

Full Wave Rectifier Output Waveform

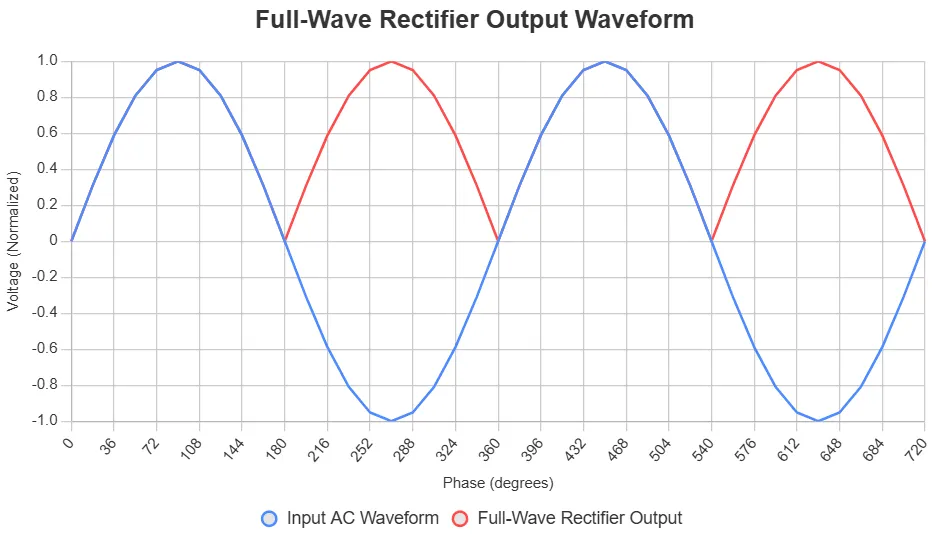

The output waveform of a full wave rectifier appears as a series of positive humps, representing the rectified AC halves. Without filtering, it pulsates at twice the input frequency, showing less ripple than half wave outputs.

This waveform is key for practical calculation guides, allowing engineers to compute averages and RMS values. In DC powered devices, smoothing capacitors transform this into near-constant voltage, essential for stable operation.

Advanced Filtering: The L-C Filter

While a simple capacitor (C-filter) is common, heavy-load applications requiring extremely low ripple utilize an Inductor-Capacitor (L-C) filter.

The inductor (L) acts as a choke, opposing changes in current flow, which further smooths the current drawn from the rectifier. The L-C filter provides a much lower ripple voltage compared to a C-filter alone, especially when the current draw is high. This approach is standard in high-power industrial power supplies.

Ripple Voltage Approximation for C-Filter: The peak-to-peak ripple voltage (Delta V) in a simple capacitive filter can be approximated by: Delta V is approximately I_load / (2 * f * C) Where I_load is the DC load current, f is the ripple frequency (twice the AC input frequency, e.g., 120 Hz in North America), and C is the filter capacitance. Engineers use this formula to calculate the minimum required capacitance value.

Voltage Regulation using ICs

For precision, the rectified and filtered voltage must pass through a dedicated regulator IC to achieve a standard, stable output voltage.

Linear Regulators (LM78xx Series): Fixed linear regulators, such as the LM7805 (for 5V output) or LM7812 (for 12V output), are commonly used. These chips take the pulsating DC input and provide a highly stable, regulated output, essential for sensitive digital electronics. A critical parameter here is the dropout voltage: the input voltage must always be at least 2 to 3 volts higher than the required regulated output voltage for the IC to function correctly.

Advantages of Full Wave Rectifier

Full wave rectifiers offer higher efficiency, reaching up to 81.2 percent, by utilizing both AC halves. This leads to lower ripple factors, around 0.48, providing smoother DC outputs. They integrate well with switch mode power supply units, enhancing overall system performance. Advantages include better voltage regulation when paired with zener diodes, making them preferable for direct current power supply needs.

Disadvantages of Full Wave Rectifier

Despite benefits, full wave rectifiers require more diodes, increasing complexity and cost. The peak inverse voltage is higher, demanding robust components. In some setups, like those with silicon controlled rectifiers, additional controls add layers. Disadvantages also include potential heat generation in high-power applications, necessitating cooling.

Full Wave Rectifier Formula and Calculations

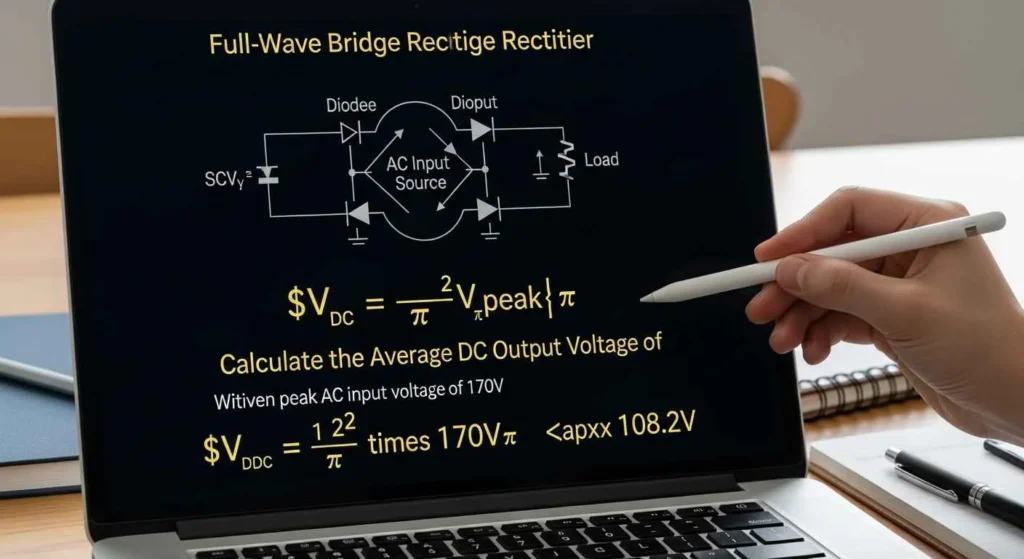

Calculations for full wave rectifiers involve key formulas for performance metrics. The average DC voltage is (2 * V_peak) / π, where V_peak is the maximum input voltage. For RMS output, it’s V_peak / √2. These formulas aid in rectifier efficiency assessments, crucial for design.

Quantitative Diode Selection and Voltage Stress

Professional design requires selecting diodes based on their maximum stress ratings, primarily Peak Inverse Voltage (PIV) and current capacity.

PIV is the maximum reverse voltage the diode must withstand when it is not conducting. Selecting a diode with a PIV rating lower than the circuit’s PIV will result in immediate diode breakdown and circuit failure.

PIV Formulas:

Bridge Rectifier (4 Diodes): The PIV applied to any non-conducting diode is simply the peak voltage of the secondary winding: PIV = V_peak.

Center Tapped Rectifier (2 Diodes): The PIV is doubled because the non-conducting diode must block the full voltage across the entire secondary winding: PIV = 2 * V_peak.

Diode Current Rating (I_FSM): In addition to the average output current, the diode must safely handle the brief, very high current spikes that occur when the filter capacitor charges. This is called the Peak Surge Current (I_FSM). Standard rectifier diodes (like the 1N4007) are designed with a high I_FSM rating (often >30A) to prevent failure during power-on or switching. This rating is critical for reliable performance, especially in battery chargers where the initial inrush current is significant.

Rectifier Efficiency

Rectifier efficiency measures how effectively AC power converts to DC, calculated as (DC power output / AC power input) * 100. For full wave, it’s approximately 81.2 percent, double that of half wave. This efficiency supports foundational rectifier concepts, especially in buck converter integrations where minimal loss is key.

Ripple Factor

The ripple factor quantifies AC remnants in DC output, given by √((V_rms / V_dc)^2 – 1), yielding 0.48 for full wave rectifiers. Lower values indicate smoother outputs. This metric is vital for electronics and circuit behavior, influencing filter designs in DC supply power systems. Practical tips include using larger capacitors to reduce ripple in power DC supply modules.

Peak Inverse Voltage

Peak inverse voltage represents the maximum reverse voltage diodes withstand, equaling 2 * V_peak in center tapped designs. Proper selection prevents breakdown.

Calculations for PIV guide component choices in full wave rectifier examples, ensuring reliability in real-world scientific applications.

In diode bridge setups, PIV is V_peak, offering advantages in certain configurations.

Half Wave vs Full Wave Rectifier

Comparing half wave and full wave rectifiers reveals stark differences. Half wave uses one diode, rectifying only half the cycle, with efficiency at 40.6 percent and ripple factor of 1.21. Full wave employs multiple diodes, achieving 81.2 percent efficiency and 0.48 ripple factor, providing twice the output frequency. Full wave excels in applications needing stable DC power, like voltage regulation in AC to DC converters.

Applications of Full Wave Rectifier

Full wave rectifiers find extensive use in DC power supplies, converting AC mains to DC for electronics. They enable voltage regulation with zener diodes, stabilizing outputs in direct current power supply units. In battery chargers, they provide efficient charging via DC power supply modules. Audio systems benefit from their low ripple, ensuring clean signals.

They power motors in industrial settings, integrating with buck converters for stepped-down voltages. In testing labs, they serve as power supplies for testing, handling AC 12V inputs. Medical devices rely on them for reliable DC powered operations, often using schottky diodes for efficiency.

Communication equipment uses them for demodulation, while voltage multipliers employ them for high DC outputs. In renewable energy, they convert inverter outputs, pairing with silicon controlled rectifiers for control.

Full Wave Rectifier in DC Power Supply

In DC power supplies, full wave rectifiers form the core, transforming AC to pulsating DC, then smoothed for use. They support voltage regulation, often with zener diodes or regulators.

This setup creates stable DC power sources, essential for electronics requiring consistent power DC supply. Bridge rectifiers are common here, offering compact designs for DC supply power needs.

Voltage Regulation with Full Wave Rectifier

Voltage regulation post-rectification maintains steady DC despite load changes. Zener diodes clamp voltages, while regulators like linear or switch mode ensure precision. In full wave setups, this integration provides reliable outputs for sensitive devices, enhancing overall system trustworthiness.

Building a Full Wave Rectifier: Step-by-Step Guide

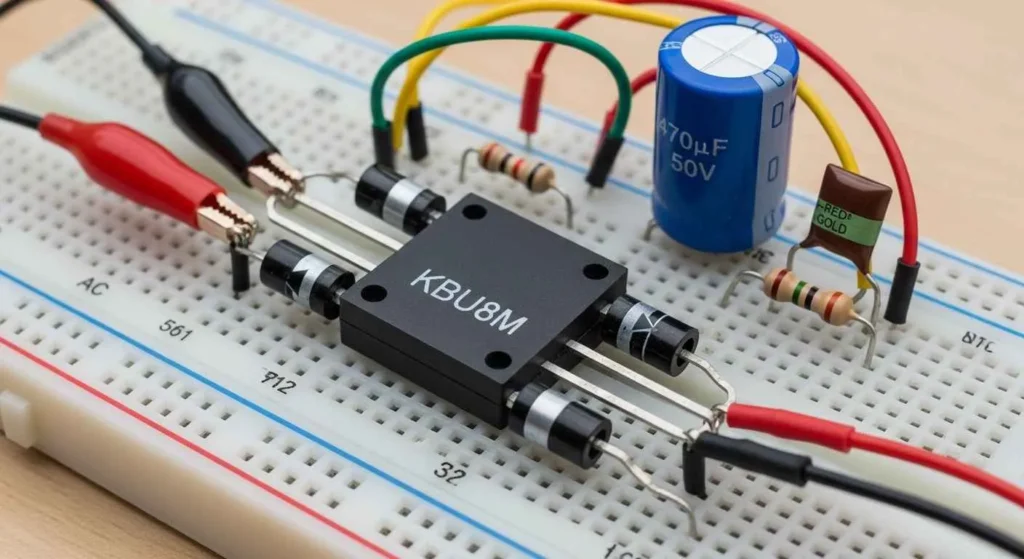

To build a full wave rectifier, start by selecting components: four diodes for a bridge, a transformer, and a load resistor. Connect diodes in bridge formation, attaching AC input to two junctions and DC output to the others.

- Add a capacitor across the output for smoothing. Test with a multimeter, observing the waveform on an oscilloscope.

- This hands-on approach demonstrates practical knowledge from electronics experiments, useful for power conversion projects.

- Safety tips include using appropriate ratings to avoid shocks, and incorporating fuses.

Simple Experiment to Observe Full Wave Rectification

Conduct an experiment by assembling a bridge rectifier on a breadboard with 1N4007 diodes and a 12V AC source. Measure output voltage, noting the pulsating DC.

- Add a 1000μF capacitor, observing reduced ripple. This illustrates real-world applications like power supplies.

- Compare with half wave by removing two diodes, highlighting differences in output quality.

Advanced Topics in Full Wave Rectifiers

Beyond basics, advanced designs incorporate silicon controlled rectifiers for phase control, enabling variable outputs. Harmonic analysis reveals impacts on power quality, mitigated by filters.

In switch mode power supplies, full wave rectifiers pair with PWM for efficient conversion. Schottky diodes reduce losses in high-frequency applications. Photo diodes occasionally integrate in optoelectronic setups, though niche.

Rectifier Properties in Electronics

Rectifier properties include forward voltage drop, reverse recovery time, and thermal characteristics. In full wave designs, these influence efficiency and reliability. For circuit design, selecting diodes with low drop, like schottky, optimizes performance in DC to DC voltage converters. Understanding these properties ensures robust full wave rectifier integration.

Rectifier Comparison Table

| Feature / Type | Half-Wave Rectifier | Full-Wave Rectifier | Bridge Rectifier |

|---|---|---|---|

| AC Utilization | Uses only one half cycle | Uses both half cycles | Uses both half cycles |

| Efficiency (η) | ~40.6% | ~81.2% | ~81.2% (slightly higher due to no center tap) |

| Ripple Factor (γ) | 1.21 (high ripple) | 0.48 (lower ripple) | 0.48 (similar to full-wave) |

| Output Frequency | Same as input (f) | Double input (2f) | Double input (2f) |

| Transformer Need | Simple, no center tap | Requires center-tap transformer | No center tap needed |

| Peak Inverse Voltage (PIV) | Vm (lower) | 2Vm (higher) | Vm (lower, better for diodes) |

| Cost & Complexity | Lowest, simplest | Moderate, needs center tap | Slightly higher (4 diodes) but no center tap |

| Applications | Low-power devices, signal demodulation | DC supplies for chargers, audio, motors | Widely used in power supplies, SMPS, battery chargers |

Troubleshooting a Full-Wave Rectifier Circuit

Diagnosing a failed power supply requires specific checks beyond simply measuring DC voltage:

Fault: Low DC Output Voltage.

Symptom: Multimeter reads low DC voltage across the load.

Fix: Use an oscilloscope to check the ripple voltage. If the ripple voltage is too high, the filter capacitor (C) has likely failed (gone short or open) or its value is insufficient for the load. Replace the capacitor with the correct microfarad and voltage rating.

Fault: No DC Output Voltage (or Half Voltage).

Symptom: DC voltage is zero, or the output frequency is halved (60 Hz instead of 120 Hz).

Fix: Use a diode test on a multimeter to check each diode in the bridge. A failed (open) diode in a bridge rectifier will often cause the circuit to behave like a much less efficient half-wave rectifier. Replace all four diodes in the bridge as a best practice.

Industry Standards and Safety Compliance

Professional rectifier designs must adhere to international safety standards to be legally sold and safely used:

IEC 60950-1 / IEC 62368-1: These International Electrotechnical Commission standards govern the Safety of Power Supplies and IT/Audio-Video equipment. Compliance ensures proper insulation, thermal protection, and fire safety in the final product.

Fuse Protection: All power supplies connected to AC mains must incorporate a fast-blow fuse on the primary side of the transformer. The fuse rating must be carefully calculated to protect the transformer windings from a short circuit fault condition in the rectifier stage.

Grounding and Isolation: Proper grounding is required to prevent electrical shock. The circuit design must clearly define the isolation boundary between the high-voltage AC input (Primary) and the low-voltage DC output (Secondary).

Expert Frequently Asked Questions (FAQs)

1. What is the standard formula for the DC output voltage of a full-wave rectifier?The average DC output voltage ( Vdc ) is calculated as: Vdc=2Vmπ Where Vm is the peak input voltage. This provides double the output of a half-wave circuit.

2. Why is the ripple factor of 0.48 significant in full-wave rectification?The ripple factor (γ) is defined as the ratio of the RMS value of the AC component to the DC component. For full-wave rectifiers:

γ=VrmsVdc2-1=0.48 This lower value means the DC output is significantly smoother than a half-wave rectifier’s 1.21.

3. How do you calculate the size of a filter capacitor for a full-wave rectifier?To achieve a specific ripple voltage ( Vr ), use the formula: C=I2⋅f⋅Vr Since full-wave rectifiers double the ripple frequency, the required capacitance is significantly reduced.

4. What is the Peak Inverse Voltage (PIV) difference between Bridge and Center-Tapped?PIV is the maximum reverse voltage across a diode. In a center-tapped rectifier, PIV=2Vm . In a bridge rectifier, PIV=Vm , making bridge circuits safer for high-voltage use.

5. What is the maximum theoretical efficiency of a full-wave rectifier?The maximum efficiency ( η ) is: η=0.8121+(Rf/RL) This reaches a maximum of 81.2%, which is exactly double the efficiency of a half-wave rectifier.

6. Why is a full-wave rectifier better for Transformer Utilization Factor (TUF)?The TUF for a full-wave bridge rectifier is 0.812. This higher ratio ensures that the transformer is utilized more effectively, allowing for smaller core sizes compared to half-wave designs.

7. Can Schottky diodes improve bridge rectifier efficiency?Yes. By replacing standard diodes with Schottky diodes, you reduce the forward voltage drop from 0.7V to approximately 0.3V , minimizing power loss.

8. What are the symptoms of a failed diode in a bridge rectifier?If one diode fails (open circuit), the DC output voltage drops, and the ripple frequency changes from

2f to f , causing an audible hum in the power supply.

9. Which industry standards apply to rectifier performance?Key standards include IEC 60146 for semiconductor converters and IEEE 519 for controlling Total Harmonic Distortion (THD) in power systems.

10. How does Silicon Carbide (SiC) technology benefit rectification?SiC diodes offer near-zero reverse recovery time, significantly reducing switching losses in high-frequency applications like EV chargers.

11. What is the role of a bleed resistor in the filter stage?A bleed resistor ensures the safety of the circuit by discharging the filter capacitor once the power is disconnected, preventing high-voltage shocks.

12. How does temperature affect the rectification efficiency?Increased temperature raises the diode’s reverse leakage current, which can lead to thermal runaway if not managed with proper heat sinks.

13. Which configuration is best for high-voltage DC conversion?The Bridge Rectifier is superior for high-voltage conversion because it eliminates the need for a center-tapped transformer and has a lower PIV requirement per diode.