Key Takeaway: A DPDT (Double Pole Double Throw) switch is a versatile 6-pin component that controls two separate circuits simultaneously. It allows you to switch between two different outputs or reverse the polarity of a circuit (commonly used for motor direction control). Unlike a standard SPDT switch, the DPDT offers dual-channel switching, making it an essential tool for complex electronics, audio equipment, and automotive projects. Hey there, fellow tinkerers and electronics enthusiasts! Today I am diving into the world of DPDT switches – those little mechanical marvels that might seem boring at first glance but are actually the unsung heroes of countless electronic projects. Trust me, once you get to know these switches, you’ll find yourself reaching for them all the time.

What is a Double Throw Switch

Ever wondered how to reverse a DC motor with just a single flip? Or how to toggle between two audio sources without a mess of wires? That’s the magic of the DPDT (Double Pole Double Throw) switch. Often called the ‘Swiss Army Knife’ of components, a DPDT switch is more than just a 6-pin toggle it’s a powerful tool that controls two separate circuits simultaneously. Whether you’re working on model trains, automotive systems, or DIY audio gear, mastering this switch is a total game-changer. Based on years of hands-on electronics tinkering, I’ve put together this ultimate guide to help you understand its wiring, pinout, and real-world applications. Let’s dive in

Understanding DPDT Switch Internal Logic

A Double Pole Double Throw (DPDT) switch is essentially two separate SPDT switches housed within a single body, operated by a single lever. This allows you to control two independent circuits simultaneously with one flip.

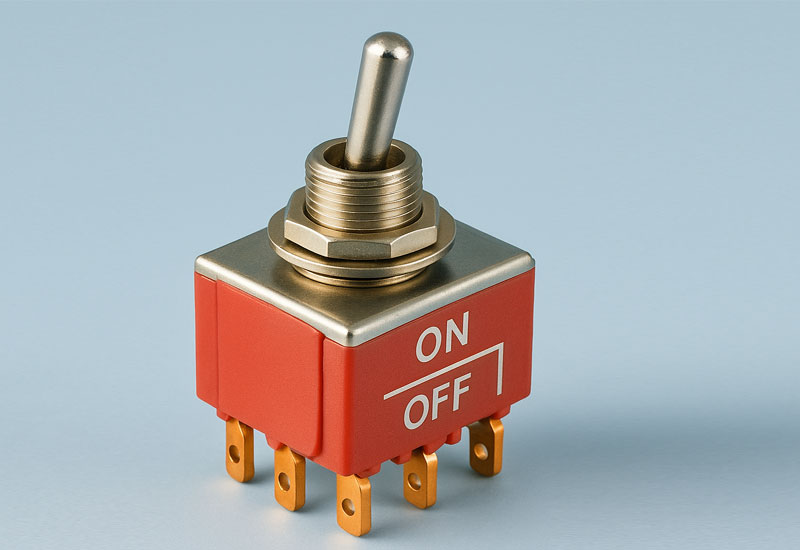

The Terminal Configuration (6-Pin Layout)

To wire a DPDT switch correctly, you must understand the 6-pin arrangement:

Pin 2 & 5 (Common/COM): These are the input pins where power enters.

Pin 1 & 4 (NC/Throw 1): Connected to COM when the switch is UP.

Pin 3 & 6 (NO/Throw 2): Connected to COM when the switch is DOWN.

What is a DPDT Switch?

What exactly is a DPDT switch? While the name sounds technical, it’s actually quite simple: a Double Pole Double Throw (DPDT) switch is essentially two separate switches (SPDT) housed in one unit, moving together with a single flip.

- Double Pole: It controls two independent circuits simultaneously.

- Double Throw: Each circuit can toggle between two different output paths.

With six terminals (2 inputs and 4 outputs), it’s not just an on/off switch it’s a router for your electricity. I always tell beginners to think of it like two light switches taped together; flipping the lever changes connections for both circuits at once. Whether it’s an On-On or On-Off-On configuration, this versatility makes it the go-to choice for complex tasks like motor reversing or dual-power switching.

The H-Bridge Concept: Reversing DC Motor Polarity

To reverse a motor, the DPDT switch must swap the positive and negative leads. This is achieved through cross-connection logic:

// Wiring for Polarity Reversal:

– Jumper Pin 1 to Pin 6 (Diagonal)

– Jumper Pin 3 to Pin 4 (Diagonal)

– Power In to Center Pins (2 & 5)

– Load (Motor) to Pins 1 & 3

This setup ensures that in Position A, current flows normally, and in Position B, the flow is inverted.

Technical Breakdown: The 6-Pin Terminal Logic

While the DPDT switch acts as a “Double Pole,” its internal mapping is what determines the circuit flow. Here is the standard pinout configuration for a 6-pin DPDT:

| Pin Number | Function | Wiring Connection |

|---|---|---|

| 2 & 5 | Common (COM) | Input Power Source |

| 1 & 4 | Throw 1 (NC) | Output Path A |

| 3 & 6 | Throw 2 (NO) | Output Path B |

Technical Specifications and Contact Physics

Understanding a switch’s physics is crucial for professional design. Beyond simple wiring, the performance of a DPDT switch is governed by electrical ratings and the physical properties of its internal contacts.

1. Key Ratings and Switching Dynamics

- Contact Rating: This specifies the maximum voltage and current the switch can safely handle (e.g., 5A at 250V AC). Operating above this threshold leads to contact welding or catastrophic failure.

- Switching Speed & Bounce: DPDT mechanical switches are slightly more complex than SPDT types because they manage two poles. Their speed is typically measured in milliseconds (ms). In high-frequency signal routing, engineers must account for “contact bounce,” where the metal plates vibrate briefly before making a solid connection.

2. Contact Resistance Formula ( Rc )

Contact resistance ( Rc) is the primary determinant of power loss ( I2R) and heat generation within the switch body. It is calculated based on the resistivity of the contact material ( ρ), the path length ( L), and the cross-sectional area ( A).

Resistivity Formula for Contact Material

R c = ρ ⋅ L A Where:

Rc= Contact Resistance (Ohms) |

ρ= Resistivity (Ω·m) |

L= Length |

A= Area

Design Implementation: Using high-conductivity materials like silver alloys or gold plating reduces

ρ, while increasing the physical contact area (

A) ensures the switch can handle high-current DC loads without overheating.

How Does a DPDT Switch Work?

Get into the nitty-gritty of how these switches actually do their thing. How does a DPDT switch work? It is all about making and breaking connections.

Inside the switch, there are two movable contacts (the “poles”) that can connect to either of two fixed contacts (the “throws”). When you flip the switch, these contacts physically move to change which connections are made. You got six terminals arranged in two rows. The middle terminals (let’s call them 1 and 4) are your “common” connections. When you flip the switch one way, terminals 1 and 4 connect to terminals 2 and 5. Flip it the other way, and they connect to terminals 3 and 6 instead.

I have found it helpful to think of it like a railroad switch that can direct a train down one of two tracks. Except here, you are directing electricity, not trains, and you are controlling two tracks at once.

The most common types you will run into are:

- ON-ON Configuration: Both positions do something. Flip it one way, you get one set of connections. Flip it the other way, you get a different set.

- ON-OFF-ON: This one has a center position that disconnects everything. Super handy when you need a neutral position.

- Momentary: These spring back to their default position when you let go – like a doorbell button.

I once spent an entire afternoon trying to figure out why my circuit wasn’t working, only to realize I had an ON-OFF-ON switch when I needed a simple ON-ON. Do not make my mistake – check your switch type before you start soldering!

Advanced Application: H-Bridge Motor Direction Control

The most powerful use of a DPDT switch is reversing the polarity of a DC motor without a microcontroller. By cross-wiring the terminals, you create a manual H-Bridge.

Wiring Logic:

1. Connect Battery (+) to Pin 2.

2. Connect Battery (-) to Pin 5.

3. Cross-wire Pin 1 to Pin 6.

4. Cross-wire Pin 3 to Pin 4.

5. Connect Motor to Pin 1 and Pin 3.

Types of DPDT Switches

Let’s talk about the different flavors of DPDT switches you might come across in your electronics adventures.

DPDT Toggle Switch

The classic! A DPDT toggle switch is what most people picture when they think of switches – it has that satisfying lever that flips up and down. I love these for projects where I want that vintage, industrial feel. For panel mounting, a DPDT toggle switch provides a durable and accessible control option. They usually come with a threaded bushing and nut that lets you mount them securely to a panel or enclosure.

Many even have waterproof boots (those rubber covers) to keep dust and moisture out. I have had toggle switches in my workshop that have survived over a decade of use. They’re built like tanks! A quality DPDT toggle switch can withstand thousands of operation cycles, which is why you’ll find them in everything from guitar amps to industrial machinery.

DPDT Rocker Switch

These are the more modern-looking cousins of toggle switches. Instead of a lever, they have a seesaw-like button that rocks back and forth. You’ve probably pressed one today without even realizing it – they’re everywhere in modern appliances.

I prefer rocker switches for projects where aesthetics matter or when I am building something that might be used by people who aren’t familiar with electronics. They’re more intuitive to use, and there’s something satisfying about that solid “click” when you press them.

DPDT Slide Switch

These little guys are perfect when space is tight. They have a tiny slider that moves back and forth. You’ll find them in smaller gadgets where there’s not enough room for a toggle or rocker.I’ll be honest they’re not my favorite for high-current applications because they’re usually rated for lower currents, but they’re perfect for signal switching or battery-powered projects. I used one in a portable radio I built, and It is been working flawlessly for years.

DPDT Relay Switch

Now we’re getting fancy! A double pole double throw relay isn’t manually operated – it uses an electromagnet to move the contacts. Think of it as a switch That is controlled by electricity rather than your finger.

I love using DPDT relays when I need to control something remotely or when the circuit I am switching has too much current to safely handle with a manual switch. They’re the unsung heroes of automation projects.

DPDT Switch Applications

So what can you actually do with these switches? Let me share some of my favorite uses.

DC Motor Control

This is probably the most common use I have found for DPDT switches. By wiring a DC motor to a DPDT switch in a specific way, you can make the motor spin forward or backward with a simple flip of the switch.

The DPDT switch for DC motor control works by reversing the polarity of the voltage going to the motor. It is like magic the first time you see it work! I built a little robot with my nephew last summer, and watching his face light up when he could make it go forward and backward with a flip of the switch was priceless.

This setup is super useful for:

- Model trains (That is how they back up!)

- RC cars and boats

- Simple robotics projects

- Power windows in cars

- Garage door openers

Audio Switching

If you are into audio projects like I am, you love DPDT switches for routing stereo signals. Since audio has left and right channels, the double pole design is perfect one pole for each channel.

I built a little A/B testing box for my home studio that lets me compare two different speakers with the flip of a switch. No unplugging and replugging cables just flip and listen.

Polarity Reversal

Beyond motors, there are tons of situations where you might want to reverse the polarity of a circuit. I have used DPDT switches for:

- LED direction control (great for indicator lights that show different colors based on direction)

- Battery charging circuits

- Testing polarity-sensitive components

I once helped a friend troubleshoot a circuit by adding a DPDT switch that let us quickly test both polarities without rewiring anything. Saved us hours of work!

Home and Industrial Automation

DPDT switches are workhorses in automation systems too:

- Security systems often use them to control dual-zone alarms

- Lighting control systems use them to manage multiple light circuits

- HVAC systems use them to switch between heating and cooling

How to Wire a DPDT Switch

Alright, let’s get practical. Learning how to wire a DPDT switch correctly will prevent circuit malfunctions and save you a lot of headaches. I learned this the hard way after frying a motor controller because I got the wiring wrong!

Basic Wiring Concepts

A DPDT switch has six terminals arranged in two rows of three. The middle terminals (pins 1 and 4) are typically your “common” connections – these connect to either the left or right terminals depending on the switch position.

For standard numbering:

- Pins 1 and 4 are the common terminals

- Pins 2 and 5 connect to one position

- Pins 3 and 6 connect to the alternative position

Motor Control Wiring: The H-Bridge Logic

How do you wire a DPDT switch for DC motor reversal?

To implement a robust DC motor reversal circuit, follow these professional steps. This configuration acts as a manual H-Bridge by swapping polarity:

- Connect Power In: Attach the Positive (+) lead to Pin 2 and the Negative (-) lead to Pin 5 (the center common pins).

- Cross-Wire the Outputs: Connect Pin 1 to Pin 6, and Pin 3 to Pin 4 using jumper wires.

- Connect the Motor: Attach the motor terminals to Pin 1 and Pin 3.

Why this works (The Physics): By cross-wiring, you are changing the direction of current flow ( I). According to Ohm’s Law:

V=I⋅R

When the switch position changes, the voltage ( V) polarity flips, forcing the motor to rotate in the opposite direction.

Safety Considerations: Lessons from the Workbench

Look, I’ve made my share of mistakes with electrical projects, so let me save you some trouble. When dealing with high-current DC or standard AC, these rules are non-negotiable:

- Check the Ratings: Ensure your switch is rated for your circuit’s voltage and current. Tip: I once used an undersized switch that melted under a high-current motor load—definitely not fun!

- Kill the Power: Always disconnect the source before wiring. Use a multimeter to verify zero voltage.

- Wire Gauge Matters: Thin wires + high current = fire hazard. Use 14-16 AWG for heavy motors.

- Secure Connections: Loose wires cause “arcing,” which generates heat and ruins the switch.

- Add a Fuse: Always place a fuse between the battery and Pin 2 to protect your circuit from shorts.

DPDT Switch Diagram and Schematic Representation

Referencing a double pole double throw switch diagram helps visualize the internal connections and operation. When I was first learning electronics, diagrams were my best friends. In schematics, DPDT switches have a specific symbol that shows all possible connections. A standard double pole double throw switch diagram shows six terminals with lines indicating how they connect in different positions. For a dpdt on on switch, the diagram shows two active positions without a center off state. When using a dpdt on on switch, both positions complete different circuits, which is perfect for applications where you need to switch between two active states rather than having an off position.

I keep a little notebook with common circuit diagrams, and my DPDT motor control wiring is dog-eared from frequent reference.

Advanced Wiring and Application Schematics

The DPDT switch implements a mechanical version of the H-bridge circuit. This allows you to quickly reverse the polarity of the voltage (

V) applied across a DC motor, ensuring bidirectional control without complex electronics.

DPDT Motor Reversal Circuit (H-Bridge Concept)

In this schematic, the cross-connections are what enable the polarity flip. The relationship between current direction and motor rotation is defined by the magnetic force law:

Force Vector Formula (

F) F→ = q ( E→ + v→ × B→ )

By reversing the current flow (

v→), the direction of the force (

F→) on the motor’s rotor is inverted.

Simplified Polarity Reversal Logic:

Position 1: Pin 2 (+V) -> Pin 1 -> Motor (+) | Pin 5 (GND) -> Pin 4 -> Motor (-) Position 2: Pin 2 (+V) -> Pin 3 -> Motor (-) | Pin 5 (GND) -> Pin 6 -> Motor (+)

Professional Application Case Studies

- Robotics and Automation: Used for controlling solenoids or linear actuators that require accurate bidirectional movement, often serving as a manual safety override or mechanical interlock.

- Audio Equipment: Essential for A/B switching between two speakers or stereo inputs. The dual-pole nature ensures both Left and Right channels switch simultaneously, preventing “ground loops.”

- Power Systems: Frequently used to toggle between a Main Load and a Dummy Load during stress testing of power supplies to maintain a constant current ( I).

Technical Deep Dive: Ratings, Formulas, and Electrical Life

Professional applications require a precise understanding of a switch’s limits beyond its simple ON/OFF function. Key factors like contact resistance and thermal management directly affect the long-term reliability and operational lifespan of the DPDT mechanism.

1. Contact Resistance and Power Dissipation ( Ploss)

Every mechanical contact introduces a small resistance ( Rc), typically in the milliohm range. This resistance causes energy to be dissipated as heat when current flows through the switch. For high-current DC applications, failing to account for this heat can lead to the housing melting or contacts welding together.

Power Loss Formula at Switch Contacts

P l o s s = I 2 ⋅ R c

Where:

I= Current (Amperes) |

Rc= Contact Resistance (Ohms)

2. Electrical and Mechanical Life (Cycle Count)

Switch durability is defined by two critical metrics that every designer must distinguish:

- Mechanical Life: The total number of operations (toggles) before physical fatigue in the spring or lever causes mechanical failure. Quality DPDT switches are often rated for 50,000 to 500,000 cycles.

- Electrical Life: The number of operations under a specific rated load (voltage and current) before the contacts degrade. Because switching power creates an electrical arc that pits or “burns” the metal, the electrical life is significantly shorter, typically between 10,000 to 100,000 cycles.

Pro Tip: To extend the electrical life of a DPDT switch in DC motor applications, consider adding a flyback diode or a snubber circuit to suppress the back-EMF arc during switching.

Industry Standards and Professional Diagnostics

1. Relevant Industry Compliance Standards

When selecting a DPDT switch for commercial or industrial use, verification of compliance is mandatory. These standards ensure the switch can handle its stated voltage and current safely:

- UL 1054 (Underwriters Laboratories): Standard for General-Use Switches. A UL listing indicates the switch meets specific safety requirements in North America.

- IEC 60947-5-1 (International Electrotechnical Commission): Governing low-voltage switchgear and control gear components, common for European industrial applications.

- NEMA Rating (e.g., NEMA 4): Defines the enclosure protection level against water, dust, and corrosive agents, essential for toggle and rocker switches in harsh environments.

2. Advanced Diagnostics: Analyzing Contact Wear

If a DPDT switch fails intermittently, a hobbyist might replace it, but an engineer performs diagnostics. Use a precision ohmmeter to check the contact resistance ($mathbf{R_c}$):

- Baseline Test: Check $mathbf{R_c}$ on a new switch (should be <100 mΩ).

- Trouble Sign: If the resistance measures above 200-500 mΩ or is highly erratic, the contacts are severely pitted, contaminated, or oxidized. This increased resistance causes excessive heat ($P_{loss} = I^2 cdot R_c$) and is a guaranteed point of failure.

Switch Specifications: Rating & Durability Standards

- Amperage (A): Ensure the switch is rated for 1.5x the motor’s stall current.

- Voltage (V): Standard switches are 125V/250V AC, but DC applications require specific DC-rated contacts to prevent arcing.

- Mechanical Life: Professional grade DPDT switches are rated for 50,000 to 100,000 cycles.

Q: What are the common DPDT switch problems and how are they fixed?

Common Failure Modes and Fixes

- Common Mistake: Motor Doesn’t Reverse (Mis-wiring)Symptom: The circuit works in one position but fails or shorts in the other.Fix: Double-check the polarity reversal diagram. The most frequent error is mis-wiring the cross-connections between the throw pins. A missing cross-connection will prevent the polarity flip.

- Symptom: Intermittent Switching or Excessive Heat at the Terminals.Cause: Contact Wear (pitting/oxidation) or Arcing. This increases contact resistance ($mathbf{R_c}$), leading to localized heating (P=I²R) and sporadic failure.Fix: Use a precision multimeter in continuity or low-resistance mode. A healthy switch should read **< 0.1 Ω (100 mΩ)** across the closed contacts. A reading above 0.5 Ω suggests contact degradation and a need for replacement.

Advantages of DPDT Switch

Why do I love these switches so much? Let me count the ways:

- Versatility: They control two independent circuits simultaneously, which opens up so many possibilities.

- Simplicity: You can achieve complex switching functions with a single component. Less parts means less that can go wrong!

- Reliability: I have DPDT switches in projects I built 15+ years ago that still work perfectly. They’re mechanical, simple, and built to last.

- Cost-Effectiveness: They’re cheaper than implementing two separate switches, and who doesn’t like saving a few bucks?

- Space Efficiency: One switch instead of two means more room for other components. This has saved me countless headaches in tight enclosures.

- Visual Feedback: You can tell the switch state just by looking at it. No guessing!

- Standardization: They come in standard sizes, so replacing them is easy if needed.

- Isolation: The two circuits remain completely electrically separated, which is crucial for some applications.

I have found these advantages particularly useful in automotive projects where space is tight and reliability is essential.

DPDT vs. Other Switch Types

When comparing spdt vs dpdt switches, the main difference is in the number of circuits they control. This is something that confused me when I first started with electronics.

SPDT vs DPDT

- SPDT (Single Pole Double Throw): Controls just one circuit that can connect to one of two outputs. It has three terminals.

- DPDT (Double Pole Double Throw): Controls two separate circuits simultaneously, each connecting to one of two outputs. It has six terminals.

The spdt vs dpdt decision comes down to whether you need to control one circuit or two. If you are just switching a single LED, an SPDT is simpler. But for stereo audio or motor direction control, you’ll need a DPDT.

DPST vs DPDT:

Another comparison that trips people up:

- DPST (Double Pole Single Throw): Controls two separate circuits but can only turn them on or off together. It has four terminals.

- DPDT (Double Pole Double Throw): Controls two circuits and can connect each to one of two different outputs. It has six terminals.

Think of DPST as a regular light switch that controls two lights at once. DPDT is more like a three-way switch that can route power in different directions.

Product Recommendations:

After trying dozens of different switches over the years, here are some that I personally recommend:

For General Electronics Projects

Carling Technologies 2GM51-73

- Rating: 20A at 125VAC

- Features: Screw terminals, ON-ON configuration

- Best for: High-current applications, industrial controls

- Price range: $15-20

- My take: These are built like tanks. I have had one controlling my shop vac for years without issues.

E-Switch 100DP3T1B1M1QEH

- Rating: 6A at 125VAC

- Features: Solder lugs, ON-OFF-ON configuration

- Best for: Audio equipment, signal switching

- Price range: $8-12

- My take: Great quality, smooth action, and the center-off position is super useful for my audio projects.

For Automotive Applications

Nilight Rocker Switch

- Rating: 20A at 12VDC

- Features: Waterproof, illuminated, snap-in mounting

- Best for: Vehicle accessories, marine applications

- Price range: $6-10 per switch

- My take: I installed these in my off-road vehicle, and they’ve survived mud, rain, and even a drink spill!

For PCB Mounting

C&K Components 7211J2ZQE2

- Rating: 0.4VA maximum

- Features: Right-angle mounting, miniature size

- Best for: Signal-level switching on circuit boards

- Price range: $2-4

- My take: Perfect for tight spaces. I use these in all my custom PCB designs.

For Heavy-Duty Applications

Signal Tech 33007 DPDT Switch

- Rating: 120VAC

- Features: Brushed stainless steel construction, integrated indicator lights

- Dimensions: 4.5″ H x 2.75″ W x 1″ D

- Price: Around $70

- Best for: Industrial control panels, high-reliability applications

- My take: Expensive but worth every penny for critical applications. I installed one in my workshop power distribution panel five years ago, and it still works like new.

Installation and Maintenance Tips

Let me share some hard-earned wisdom about keeping your switches working reliably:

- Mounting: Make sure It is secure! A loose switch will cause intermittent problems that will drive you crazy. I always use lock washers with my panel-mount switches after one vibrated loose in a mobile application.

- Wiring: Use the right wire gauge for your current. I prefer stranded wire for most applications because it handles vibration better than solid wire.

- Strain Relief: Do not pull on those wires! I add a dab of hot glue or a zip tie as strain relief to prevent tugging on the terminals.

- Sealing: For outdoor projects, get switches with proper IP ratings. I learned this lesson after rain killed a project I left outside.

Maintenance

- Regular Inspection: I check my switches every few months for loose connections or signs of wear.

- Contact Cleaning: If a switch starts acting flaky, a shot of contact cleaner can often bring it back to life. I have rescued several “dead” switches this way.

- Lubrication: Some switches benefit from a tiny drop of electronic-grade lubricant. Just be careful not to overdo it!

- Replacement Schedule: For critical applications, I replace switches preventively before they fail. Better safe than sorry!

How to Choose the Right DPDT Switch?

| Selection Factor | What to Consider |

|---|---|

| Voltage & Current Ratings | Choose a switch with ratings higher than the maximum voltage & current in your circuit to prevent overheating, failure, or fire hazards. |

| Actuator Type |

|

| Terminal Type |

|

| Mounting Style |

|

| Environmental Protection | Choose sealed switches (IP65/IP67) for applications exposed to water, dust, or harsh environments. Ensure the switch’s operating temperature range aligns with the environmental conditions. |

| Certifications & Safety Marks | Look for switches with certifications like UL, CE, CSA, and RoHS for safety, quality assurance, and legal compliance. |

| Size and Shape | Ensure the switch fits within the available space in your design. Large switches are suitable for heavy-duty use; smaller switches are ideal for compact applications. |

| Contact Action Type |

|

| Durability (Life Cycle Rating) | Check the rated number of actuations (cycles) the switch can endure. Higher cycle ratings are important for switches subjected to frequent or continuous use. |

| Price & Availability | Choose basic, cost-effective switches for simple, low-stress applications. For critical or long-term use, invest in high-quality, durable brands. |

Applications

In control rooms, two indicator lights are used to show the status of valve positions: one for “on” and one for “off,” ensuring the switch is operating correctly regardless of its position. When selecting switches, choose models with stiffer contact springs and durable materials to resist dirt, debris, and prevent freezing in cold environments. Off-the-shelf switches often face issues with frozen mechanical internals, which can disrupt their functionality.

Industry Compliance and Safety Standards (IEC & UL)

Q: Is a DPDT switch UL certified? Industry Standards Explained

Mandatory Certifications for Switches

Safety Note: Always Disconnect Power

- IEC 60669 (Switches for Household and Similar Fixed Electrical Installations): This is the key international standard governing the performance and safety requirements (like endurance and heat resistance) for manual switches used globally.

- UL Certification (Underwriters Laboratories): The UL mark indicates that the switch has been rigorously tested to meet North American safety standards, which is crucial for preventing fire and electrical shock. Always choose UL-listed components.

Safety Note: Always Disconnect Power

Before performing any wiring, inspection, or troubleshooting especially when dealing with AC voltages or high-current DC loads always ensure the circuit power source is completely disconnected and verified off using a non-contact voltage tester and a multimeter. Safety is paramount.

Conclusion: Why DPDT Switches Deserve Some Love

After spending way too many hours playing with these switches over the years, I have come to appreciate their elegant simplicity and incredible versatility. From simple projects to complex systems, DPDT switches offer reliable control that just works.

Whether you are a hobbyist working on your first motor control project or a seasoned engineer designing industrial systems, I hope this guide has given you some useful insights into the world of DPDT switches.

Remember that proper selection, wiring, and installation are key to getting the most from these versatile components. Consider your voltage and current requirements, environmental conditions, and specific application needs when choosing the right switch for your project.

Got questions about using DPDT switches in a specific application? Drop a comment below! I love hearing about creative uses for these humble but powerful components.

FAQ for DPDT Switch

1. What does DPDT stand for?

DPDT stands for Double Pole Double Throw. It means the switch has two independent poles (circuits) and each pole can connect to two different throws (positions).

2. How many terminals are on a DPDT switch?

A standard DPDT switch has 6 terminals (pins). Two are Common (input), and four are Output terminals.

3. Can I use a DPDT switch as an On/Off switch?

Yes, by using only one set of terminals, you can use it as a standard power switch, although it is designed for more complex routing.

4. How do I reverse a DC motor with a DPDT?

By cross-wiring the output pins in an ‘X’ pattern, you can flip the polarity sent to the motor, reversing its direction.

5. What is an ON-OFF-ON DPDT switch?

This is a 3-position switch where the center position is ‘OFF’, meaning no connection is made in the middle state.

6. What is the difference between DPDT and SPDT?

SPDT (Single Pole) controls one circuit; DPDT (Double Pole) controls two separate circuits simultaneously.

7. What is the difference between DPDT and DPST?

DPST is a simple ON/OFF for two circuits. DPDT can switch those two circuits between two different paths.

8. What are ‘Momentary’ DPDT switches?

Momentary switches only stay in a position as long as you hold them. They spring back to the center or default position when released.

9. Can I switch AC and DC with the same DPDT?

Technically yes, but you must check the voltage and current rating for each. AC ratings are usually higher than DC ratings for the same switch.

10. What terminal is the ‘Common’ pin?

In a 6-pin DPDT, the middle two pins (usually labeled 2 and 5) are the Common terminals.

11. Why is my DPDT switch sparking?

Sparking (arcing) happens if the load is too high or if you are switching a high-voltage DC circuit without an arc-suppression capacitor.

12. How do I test a DPDT switch with a multimeter?

Set the multimeter to ‘Continuity’ mode and check for a ‘beep’ between the Common pin and the output pins in different switch positions.

13. What gauge wire should I use with a DPDT switch?

It depends on your current (Amps). For small electronics, 22AWG is fine, but for high-power motors, 14AWG or 12AWG is recommended.

Pin 2 & 5 (Common/COM): These are the input pins where power enters.

Pin 2 & 5 (Common/COM): These are the input pins where power enters. Pin 1 & 4 (NC/Throw 1): Connected to COM when the switch is UP.

Pin 1 & 4 (NC/Throw 1): Connected to COM when the switch is UP. Pin 3 & 6 (NO/Throw 2): Connected to COM when the switch is DOWN.

Pin 3 & 6 (NO/Throw 2): Connected to COM when the switch is DOWN.

Helpful info. Lucky me I found your web site unintentionally, and I am surprised why this twist of fate didn’t happened earlier! I bookmarked it.