DC Machines: Key Takeaways Summary

DC machines are versatile electromechanical devices that convert electrical energy to mechanical motion (motors) or mechanical energy to electrical power (generators). They offer high starting torque, precise speed control, and reliable operation across industries including electric vehicles, robotics, renewable energy systems, and industrial automation. Key components like the commutator and brushes enable unidirectional current flow, while different configurations (shunt, series, compound, brushless) cater to specific application needs. With efficiency reaching 85-95% and compliance with IEEE, IEC, and NEMA standards, DC machines remain essential in modern engineering despite requiring more maintenance than AC alternatives. Proper selection based on torque requirements, speed regulation, and environmental conditions ensures optimal performance and longevity.

Table of Contents (Click to Open / Close)

- Introduction to DC Machine

- What is a DC Machine?

- History and Evolution of DC Machines

- Types of DC Machines

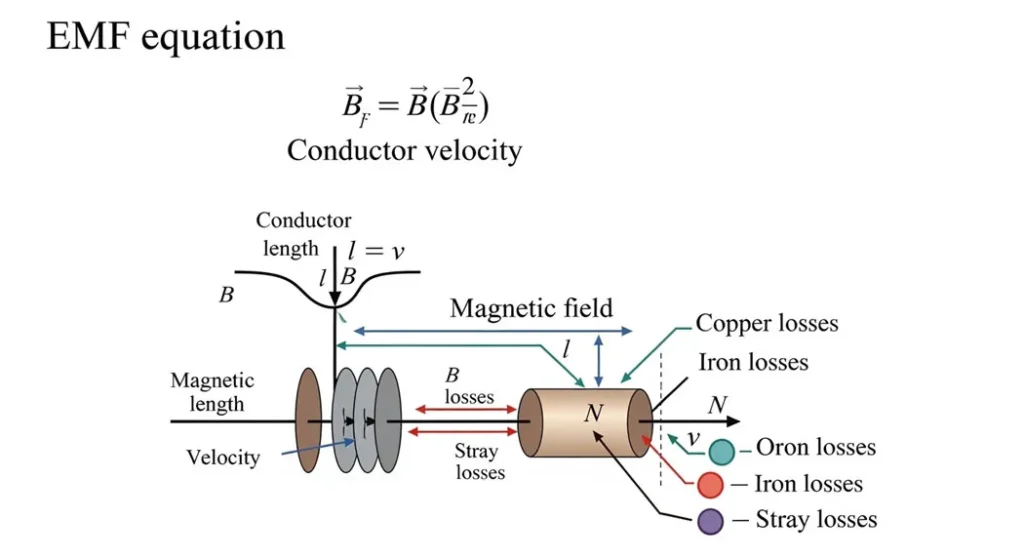

- The EMF Equation and Losses

- Real-World Applications and Performance Case Studies

- DC Motor Type Comparison

- Quantitative Mechanics

- Applications of DC Machines

- Advantages and Disadvantages

- DC Machines vs. AC Machines

- Buyer’s Guide: How to Choose the Right DC Machine

- Advanced Diagnostics and Predictive Maintenance Metrics

- Quantitative Troubleshooting: Symptoms, Causes, and Solutions

- Conclusion

- Industry Standards and Certification

- FAQ (Frequently Asked Questions) About DC Machines

Introduction to DC Machine

In today’s world of electric vehicles, precision robotics, and renewable energy, the DC machine remains a cornerstone of power conversion. Acting as both motor and generator, it delivers high starting torque, precise speed control, and reliable energy conversion that drive innovation across industries. From smooth EV acceleration to stable renewable storage, DC machines embody versatility and efficiency. This guide distills their essentials construction, key EMF formula, commutator role, motor types, losses, standards (IEEE, IEC, NEMA), and buying insights so engineers, students, and buyers can connect theory with real‑world applications, costs, and compliance.

What is a DC Machine?

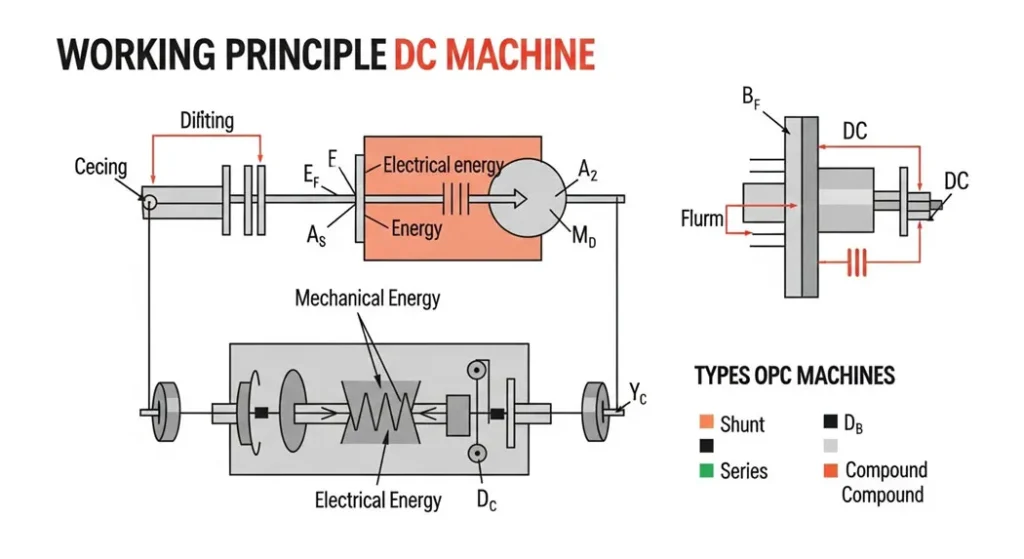

A DC machine functions as an electromechanical converter that relies on direct current to perform its tasks, either transforming electrical input into mechanical output in the case of a motor or converting mechanical energy into electrical power as a generator. To illustrate, imagine a DC motor efficiently driving a conveyor system in a busy warehouse, where precise control over speed and torque is essential, or a DC generator in a remote solar installation capturing rotational energy from turbines to charge batteries reliably. What sets DC machines apart from their AC counterparts is their ability to maintain unidirectional current flow, which allows for straightforward adjustments in speed through voltage changes, making them highly adaptable for scenarios demanding accuracy.

The commutator, a key innovation in DC machines, acts as a rotary switch that ensures the internal alternating currents are rectified into a consistent DC output, a design principle documented in IEEE Std 1180 and refined in modern industrial practice by manufacturers like ABB and Siemens to meet global reliability standards. addressing queries about how these devices achieve steady performance. This component not only enhances reliability but also positions DC machines as ideal for specialized roles, ranging from traditional automotive starters to advanced propulsion in drones. For further foundational understanding, you can refer to explanations of Faraday’s law, which underpins their electromagnetic operation.

History and Evolution of DC Machines

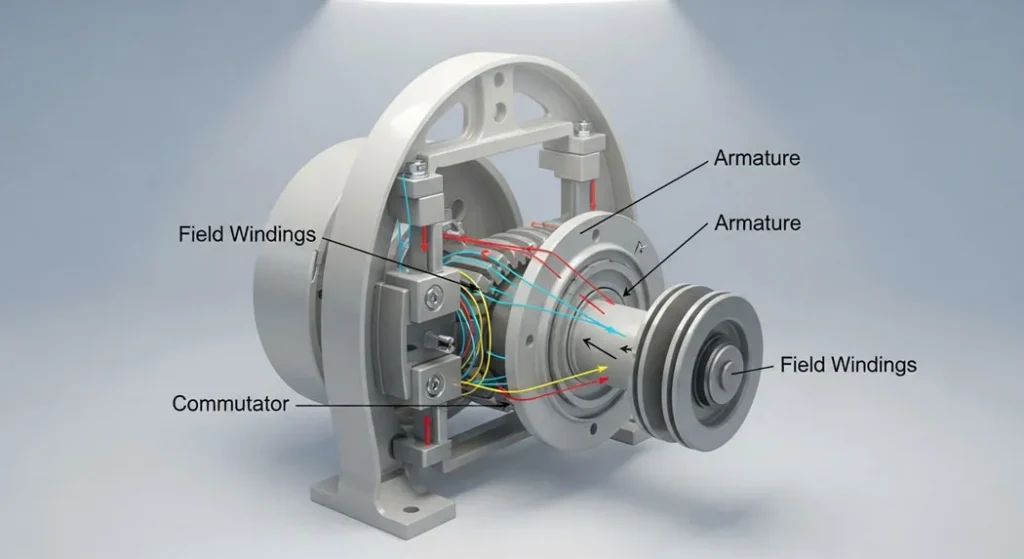

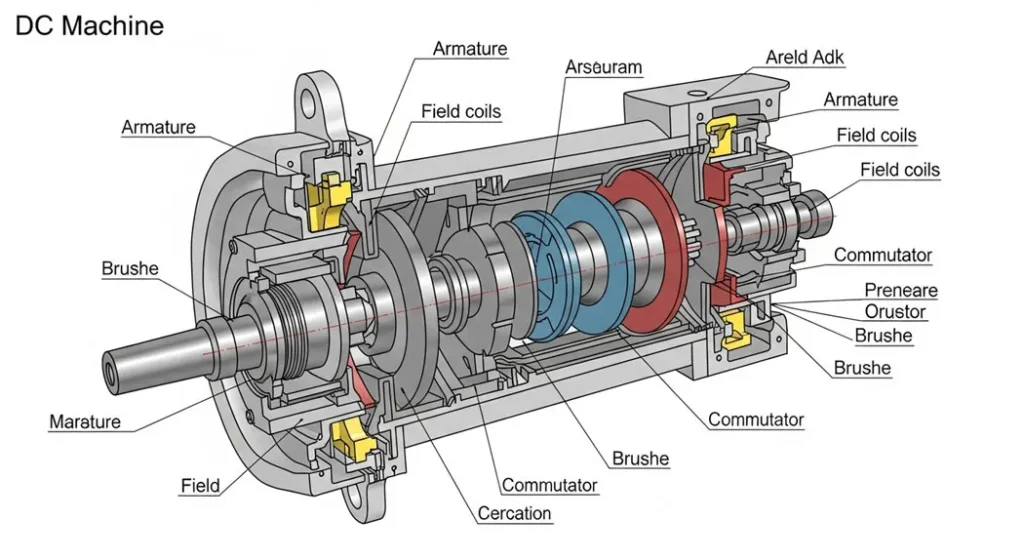

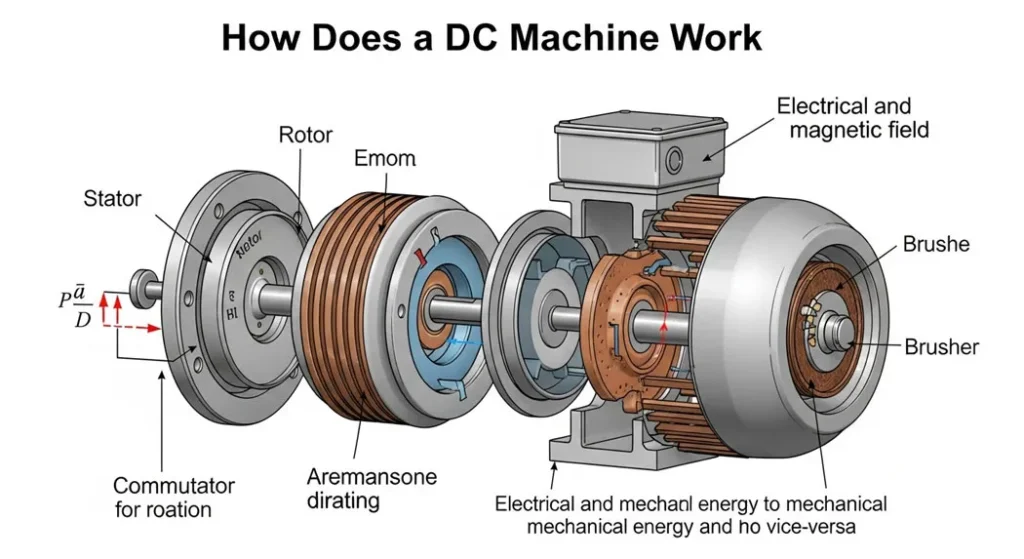

A DC machine is built for seamless energy conversion, with each part serving a precise role. The yoke forms the backbone, guiding magnetic flux and shielding internals. Pole cores and field coils generate flux, while laminated steel reduces eddy losses. The armature core houses copper windings that interact with the field to produce torque or voltage. A commutator and carbon brushes rectify current, ensuring steady DC output. Pole shoes spread flux for efficiency, and bearings (often SKF/NSK, IEC 60034‑14 compliant) minimize friction and extend service life. Together, these components form a mechanical orchestra, harmonizing to deliver reliable power conversion.The operation of a DC machine hinges on electromagnetic interaction. In motors, field coils create a magnetic field while armature current produces torque via the Lorentz force, with the commutator ensuring unidirectional motion (Fleming’s left‑hand rule). In generators, mechanical rotation induces EMF by Faraday’s law, balanced by Lenz’s law, with the commutator rectifying output to DC. Efficiency typically reaches 85–95% under IEC 60034‑2‑1 standards, validated in IEEE studies of EV drivetrains. Applications include pumps and robotics, where consistent torque and precise control are vital. Modern advances like wireless servosystems further enhance response and reduce energy waste, making DC machines a preferred choice for precision tasks.

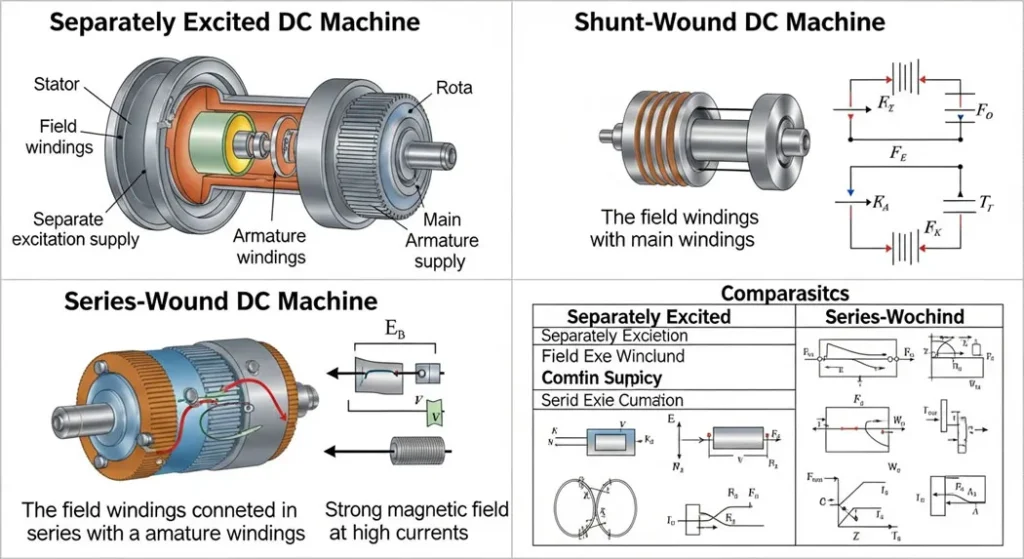

Types of DC Machines

DC machines are classified by field excitation, each offering distinct performance. Separately excited motors use an independent source for precise flux and speed control, ideal in labs and robotics. Shunt‑wound motors connect the field in parallel, maintaining steady speed under varying loads, common in fans and conveyors. Series‑wound motors, with field in series, deliver immense starting torque for cranes and locomotives but show speed fluctuation at light loads. Compound‑wound motors blend shunt stability with series torque, serving elevators and rolling mills. Modern brushless DC machines employ electronic commutation, achieving up to 98% efficiency in EVs per IEEE benchmarks, eliminating brushes for longer life and minimal losses.

| Type | Winding Configuration | Key Characteristics | Typical Applications | Torque-Speed Curve |

| Separately Excited | Independent DC source for field | Precise control; constant flux | Labs, robotics, traction | Stable speed |

| Shunt-Wound | Field parallel to armature | Constant speed; low starting torque | Fans, pumps, conveyors | Drooping (stable) |

| Series-Wound | Field in series with armature | High starting torque; variable speed | Cranes, locomotives | Hyperbolic (high torque, low speed) |

| Compound-Wound | Series + shunt (cumulative/differential) | Balanced torque/speed; overload protection | Elevators, mills | Flat with droop |

| Brushless DC | Electronic switching | High efficiency; low maintenance | EVs, drones, appliances | Efficient across ranges |

The EMF Equation and Losses

Central to evaluating DC machine performance is the electromotive force equation, which calculates the generated or back EMF as E_b = (P φ N Z) / (60 A), where P represents poles, φ flux per pole in webers, N speed in RPM, Z armature conductors, and A parallel paths. For instance, in a four-pole lap-wound generator with 200 conductors, 0.05 webers flux, and 1200 RPM, the EMF approximates 200 volts, providing a practical way to predict output.

However, real-world efficiency is impacted by various losses, which must be minimized for optimal operation. Copper losses stem from resistive heating in windings, often comprising 40% to 50% of total inefficiencies and mitigated through larger conductors or cooling systems. Iron losses, including hysteresis and eddy currents in the core, account for 20% to 30% and are reduced via lamination and high-grade materials. Mechanical losses from bearing and brush friction contribute 10% to 15%, addressed with lubrication, while brush contact resistance adds 5% to 10%, improvable with advanced graphite. Stray losses, such as windage and flux leakage, make up the remaining 5% to 10%, minimized by streamlined designs. The table below details these losses for a commanding overview:

| Loss Type | Cause | Mitigation | Typical % of Total |

| Copper | I²R in windings | Larger conductors, cooling | 40–50% |

| Iron | Hysteresis/eddy in core | Lamination, high-grade steel | 20–30% |

| Mechanical | Bearing/brush friction | Lubrication, low-friction materials | 10–15% |

| Brush | Contact resistance | Graphite upgrades | 5–10% |

| Stray | Windage/flux leakage | Streamlined design | 5–10% |

As noted in a 2025 ABB whitepaper and supported by IEEE research on improved converters, targeted optimizations can cut copper losses by up to 18%. EMF is generated by the interaction of conductors with the magnetic field, governed by Faraday’s Law, with standardized calculation methods documented in IEEE Std 1812 and applied in both academic and industrial performance models.

However, efficiency is tempered by losses. Copper losses arise from resistance in the armature and field windings, generating heat like a glowing filament. Iron losses, including hysteresis and eddy currents, occur in the magnetic core, akin to friction in a spinning wheel. Mechanical losses stem from friction in bearings and brushes, while stray losses account for miscellaneous inefficiencies. Brush losses, due to contact resistance, further reduce output. Minimizing these losses is like tuning a racecar, ensuring peak performance for applications like electric vehicles or industrial drives.

However, efficiency is tempered by losses. Copper losses arise from resistance in the armature and field windings, generating heat like a glowing filament. Iron losses, including hysteresis and eddy currents, occur in the magnetic core, akin to friction in a spinning wheel. Mechanical losses stem from friction in bearings and brushes, while stray losses account for miscellaneous inefficiencies. Brush losses, due to contact resistance, further reduce output. Minimizing these losses is like tuning a racecar, ensuring peak performance for applications like electric vehicles or industrial drives.Real-World Applications and Performance Case Studies

The selection of a DC machine type is determined by the load requirements, primarily dictated by its Speed Regulation and Torque Characteristics.Series DC Motor: High Traction

Due to its high starting torque (T∝I2), the Series motor is ideal for traction applications where a massive initial force is required.- Application: Electric Railways, Hoists, Cranes.

- Characteristic: Highly variable speed; dangerous at no-load.

- Metric: Torque can be 400% to 500% of rated torque at starting.

Shunt DC Motor: Constant Speed

The shunt field flux (ϕ) is nearly constant, resulting in near-constant speed regardless of load change, making it suitable for precision work.- Application: Lathes, Milling Machines, Fans, Blowers.

- Characteristic: Excellent speed regulation.

- Metric: Speed regulation is typically less than 5% from no-load to full-load.

Compound DC Motor: Load Handling

Combining the high starting torque of the series winding with the controlled speed of the shunt winding provides a balanced performance for dynamic loads.- Application: Elevators, Punch Presses, Rolling Mills.

- Characteristic: Better speed stability than series, higher starting torque than shunt.

- Metric: Offers a 150% to 200% starting torque margin while maintaining stable speed under sudden load variations.

DC Motor Type Comparison

| Type | Speed Characteristic | Torque | Common Applications |

|---|---|---|---|

| Series | Variable (Inverse N∝1I) | High Starting Torque | Cranes, Traction (Railways) |

| Shunt | Nearly Constant <5% speed regulation) | Moderate/Stable | Lathes, Fans, Centrifugal Pumps |

| Compound | Balanced (Drops slightly with load) | High Starting, Moderate Running | Elevators, Punch Presses |

Quantitative Mechanics: Armature Torque (Ta)

The mechanical power produced by a DC motor is directly related to the Armature Torque (Ta), which is the force that generates rotation. This is the central equation for sizing a motor for a specific load (e.g., an elevator or a crane).The DC Motor Torque Equation

Torque is directly proportional to the magnetic flux (ϕ) and the armature current (Ia):Worked Example: Current Calculation

Scenario: A motor is rated for 100N⋅m of torque. If the motor constant and flux are known (Ka⋅ϕ=20), the required armature current (Ia) must be::Calculation: Ia=TaKa⋅ϕ=100N⋅m20=5Amps..Conclusion: This calculation dictates the minimum size of the power electronics (drives) and the conductor size needed for the armature windings.

Applications of DC Machines

DC machines stand out for precise control and robust performance. In EVs, series and brushless motors deliver instant torque, regenerative braking, and >90% efficiency, as seen in the Tesla Model 3. Shunt motors keep pumps and fans at constant speed, while compound types manage variable loads in mills. In renewables, DC generators charge batteries in solar‑wind hybrids, and brushless variants power appliances quietly. A 2024 Siemens case study showed 22% energy savings from DC motor tuning, highlighting industrial impact. By 2025, brushless DC motors are fueling EV growth with extended ranges and reduced EMI, pushing the market past $11B, proving their adaptability to sustainability demands.

Leading Manufacturers and Global Brands

When sourcing DC machines, international reputation and certification matter. Globally recognized brands include Siemens (Germany), ABB (Switzerland), General Electric (USA), Toshiba (Japan), and WEG (Brazil). These companies design machines that meet IEC (International Electrotechnical Commission) and IEEE standards, ensuring safety, durability, and high performance. Opting for standard-compliant brands reduces downtime and ensures compatibility with modern drives and automation systems.

Cost Breakdown of DC Machines

Pricing varies by size, brand, and efficiency class. Small motors under 5 HP may range between USD $200–$800, while medium machines (5–50 HP) can cost $1,000–$5,000. Large industrial-grade DC machines often exceed $10,000, with advanced energy-efficient models reaching $50,000+. According to IEEE market surveys, the average industrial DC machine costs around $200–$300 per HP, though high-efficiency options can climb to $500/HP.

Advantages and Disadvantages

DC machines offer notable benefits that make them indispensable in specific contexts. Their capacity for high starting torque, up to five times rated values in series configurations, suits heavy loads, while precise speed and torque adjustments via armature voltage control excel in robotics. Additionally, they operate without harmonics for smoother performance and allow easy direction reversal by swapping leads. On the downside, the need for regular brush and commutator maintenance, typically every 2,000 hours, increases operational costs, and their higher initial price compared to AC options can be a barrier. Efficiency may lag in ultra-high-power applications above 100 kW, and potential sparking limits use in hazardous areas.

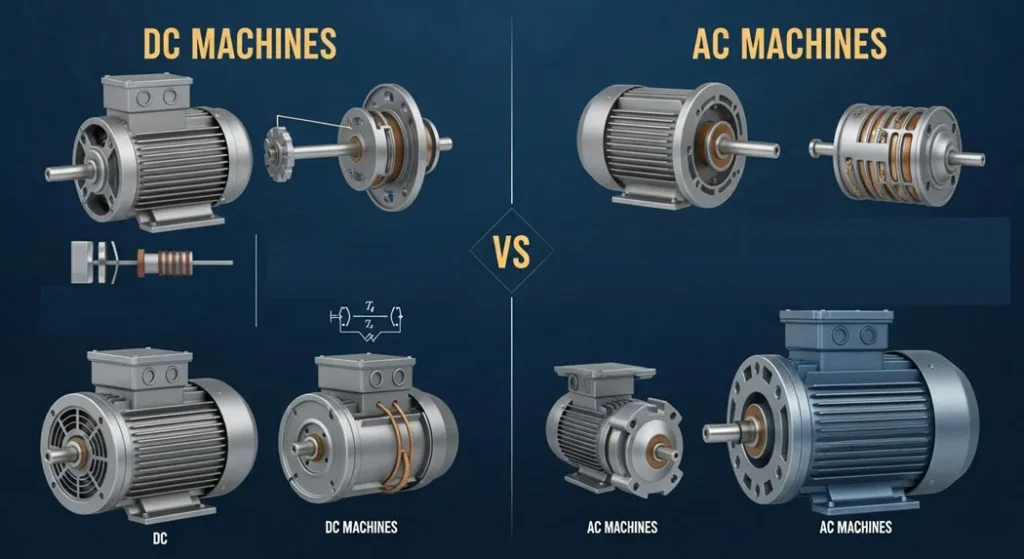

DC Machines vs. AC Machines

When comparing DC and AC machines, several factors highlight their respective strengths, helping to clarify selection decisions. DC machines operate on direct current for superior speed and torque control via simple voltage adjustments, featuring mechanical commutation with brushes and a rotating armature in a static field, which suits applications like EVs needing precision. In contrast, AC machines use alternating current, often with three-phase inputs, eliminating brushes for lower maintenance and excelling in high-power, constant-speed scenarios like grid pumps, thanks to their static armature and rotating field. Efficiency favors AC at higher powers due to fewer losses, but DC provides higher starting torque and reversibility. The table below offers a commanding comparison:| Aspect | DC Machines | AC Machines |

| Power Source | DC (precise control) | AC (grid-friendly) |

| Commutation | Mechanical (brushes) | None (squirrel cage) |

| Speed Control | Excellent (voltage/rheostat) | Good (VFDs) |

| Maintenance | Higher (brushes) | Lower |

| Efficiency | High torque, low speed | High power, constant speed |

| Cost | Higher initial | Lower for large-scale |

Buyer’s Guide: How to Choose the Right DC Machine

Choosing a DC machine involves aligning specifications with your requirements, such as selecting a shunt type for steady loads or series for high-torque starts. Key considerations include power ratings from 0.5 to 500 kW, calculated as power equals torque times angular velocity, voltage levels of 12 to 600V to minimize losses, efficiency classes like IE3 or IE4 for long-term savings, and IP ratings above 54 for environmental protection. Certifications such as IEC 60034 ensure safety and compatibility.To verify fit, review torque-speed curves, opt for totally enclosed fan-cooled enclosures in dusty settings, and allocate a 20% budget for maintenance. Testing with a dynamometer confirms performance. In 2025, market analyses indicate that selecting energy-efficient models can yield significant ROI, with the global DC electric motor sector projected to expand from $48.19 billion, reflecting growing demand in EVs and automation.

Leading Manufacturers and Cost BreakdownReputable manufacturers ensure quality and compliance with standards like IEC and IEEE. Siemens from Germany specializes in precision-engineered solutions, ABB from Switzerland leads in energy-efficient brushless designs, General Electric from the USA offers robust industrial options, Toshiba from Japan provides compact innovations, and WEG from Brazil delivers cost-effective global products.

Cost estimates for 2025 vary: units under 5 HP range from $250 to $900, 5 to 50 HP from $1,200 to $6,000, and over 50 HP from $8,000 to $60,000, with per-HP pricing at $200 to $400 base, plus 25% for premiums. These figures align with reports from MarketsandMarkets and Fortune Business Insights. For fractional HP DC motors, values are projected around $4.8 billion globally by end-2025.

Advanced Diagnostics and Predictive Maintenance Metrics

Modern DC machine maintenance relies on quantitative testing protocols to prevent catastrophic failures, especially concerning winding insulation and mechanical stability. Effective maintenance involves quarterly brush inspections and shaft alignments to prevent issues. Common problems like overheating can be resolved by improving ventilation, while sparking often requires adjusting brush gaps to 1-2 mm. Implementing IoT sensors for predictive monitoring can reduce downtime by 30%, as per Deloitte insights.Winding Integrity: Insulation Resistance (IR) Testing

Insulation degradation is the primary cause of motor failure. The integrity of the winding insulation is measured using a Megohmmeter (or Megger), which applies a high DC voltage (e.g., 500V or 1000V)and measures the resulting resistance.- Minimum Standard (IEEE 43-2013): The insulation resistance (IR) should be at least 1MΩ plus 1MΩ per kilovolt of machine rating. For a 600V machine, the minimum IR should safely exceed 1.6MΩ.

- Troubleshooting Short: A low IR reading indicates moisture contamination or physical insulation damage (a ground fault), requiring immediate repair or replacement.

Mechanical Diagnostics: Vibration Analysis

Excessive vibration is a key indicator of mechanical failure (bearing wear, rotor imbalance, or shaft misalignment). Vibration is quantified and monitored using accelerometers.- Severity Metric: Vibration severity is typically measured in mm/s (velocity). The IEC 60034-14 standard defines acceptable limits based on the machine’s size and operating speed.

- Failure Diagnosis: Specific vibration frequencies can diagnose the source: high amplitude at 1×RPM often indicates imbalance, while high-frequency noise suggests advanced bearing degradation.

Quantitative Troubleshooting: Symptoms, Causes, and Solutions

Diagnosing DC machine faults relies on identifying visible symptoms (e.g., sparking) and tracing the mechanical or electrical cause.Fault 1: Excessive Sparking at the Commutator

- Symptom: Bright blue or yellow sparking visible under the brushes.

- Cause: High current density due to incorrect Brush Wear or Armature Reaction.

- Fixes:

- Primary: Check brush length and pressure; replace if worn below acceptable limits (typically 25% of original length).

- Advanced: Verify Interpoles or Compensating Windings are correctly connected to counteract the distorted flux (Armature Reaction)

Fault 2: Overheating and Burnt Smell

- Symptom:Commutator temperature exceeds rated limits (check thermal sensors) and a burnt phenolic smell.

- Cause: Excessive Copper Losses (overloading) or a high resistance path in the commutator segments.

- Fixes:

- Primary: Use a Tachometer to verify the machine isn’t running below its rated speed (overloaded).

- Advanced: Clean and Resurface the commutator segments to remove carbon dust buildup and eliminate short circuits between segments.

Conclusion

DC machines form the backbone of contemporary engineering, enabling seamless energy conversions that power electric transport and renewable infrastructures. By understanding their intricate designs and electromagnetic foundations, you gain the tools to optimize systems effectively. For personalized guidance, reach out to Procirel experts.

Industry Standards and Certification

DC machine performance, safety, and testing protocols are defined by global organizations to ensure interchangeability and reliability across industries.Testing and Performance Standards

- IEEE Std 112: The industry-standard procedure for Testing Polyphase Induction Motors and Generators. While focused on AC, it establishes the rigorous test methods (dynamometer, calculation of efficiency and losses) used universally for all rotating electrical machines, including DC types.

- IEC 60034 Series: The comprehensive international standard covering all aspects of Rotating Electrical Machines, including efficiency classes, vibration limits, thermal performance, and terminal markings.

- NEMA MG1 (Motors and Generators): The North American standard specifying the Motor Performance, Safety, and Dimensions. Compliance ensures the motor will physically fit and operate according to its datasheet in US and Canadian industrial environments.

FAQ (Frequently Asked Questions) About DC Machines

1. What is the fundamental function of a DC machine?

A DC machine is an electromechanical energy converter. It operates bidirectionally: as a motor, it converts electrical energy into mechanical torque; as a generator, it transforms mechanical rotation into direct current (DC) electrical output.2. What is the role of a commutator in DC machine operation?

The commutator acts as a mechanical rectifier. In motors, it constantly reverses the current direction in the armature windings to maintain unidirectional torque. In generators, it rectifies the internal alternating current (AC) into a steady DC output for external use.3. Why are DC motors preferred for Electric Vehicles (EVs) and Traction?

DC motors, specifically Series and Brushless (BLDC) types, provide high starting torque (up to 500% of rated capacity). This is critical for moving heavy stationary loads. Additionally, they allow for precise speed control and regenerative braking, which improves battery efficiency.4. How do Shunt and Series DC motors differ in performance?

The difference lies in their speed-torque characteristics:- Shunt Motors: Field windings are in parallel; they offer nearly constant speed, making them ideal for lathes and fans.

- Series Motors: Field windings are in series; they provide massive starting torque but variable speed, making them perfect for cranes and locomotives.

5. What are the primary losses that affect DC machine efficiency?

Efficiency is typically reduced by 5% to 15% due to:- Copper Losses: Resistive heating in windings ($I^2R$).

- Iron Losses: Hysteresis and eddy currents in the core.

- Mechanical Losses: Bearing friction and windage.

- Brush/Stray Losses: Contact resistance and flux leakage.