🔧 Quick Summary

Imagine you’re in the middle of a critical test in a buzzing industrial plant, and your moving iron ammeter starts giving wonky readings. Frustrating, isn’t it? Moving iron repulsion type instruments, like ammeters and voltmeters, are reliable workhorses for electrical measurements, but they need regular care to stay accurate. This guide is here to help electrical engineers, technicians, and lab professionals keep these analog instruments in top shape. We’ll walk you through calibrating and maintaining them with simple steps, practical troubleshooting tips, and best practices to ensure precision and a long lifespan.

Understanding Moving Iron Repulsion Type Instruments

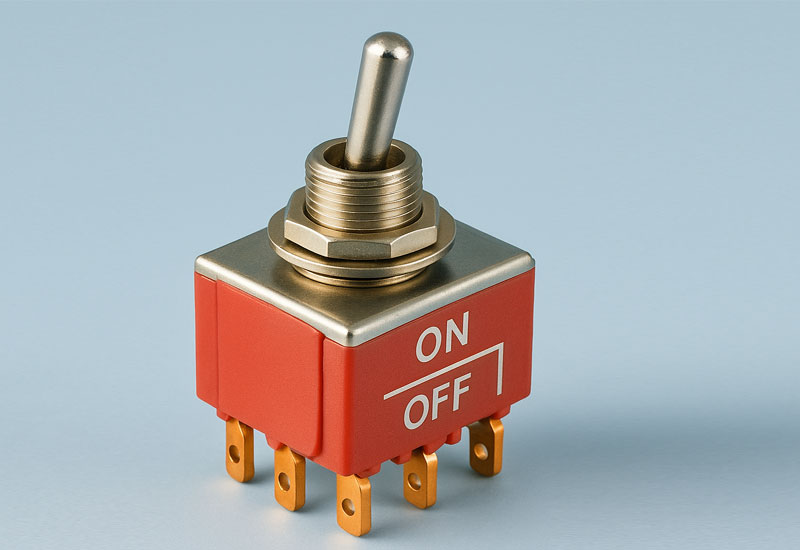

Moving iron repulsion type instruments measure electrical current or voltage using the repulsion between two iron pieces in a magnetic field, which moves a needle across a scale. You’ll find them in power plants, industrial settings, or labs where accurate electrical measurements are crucial. Unlike digital meters, these instruments are rugged and handle both AC and DC without fancy electronics. But dust, wear, or improper handling can throw off their accuracy, so regular calibration and maintenance are key.

These devices shine in tough environments where durability matters more than high-tech features. Knowing how they work and how to care for them ensures they keep delivering reliable results.

Step-by-Step Calibration Process

Calibrating a moving iron instrument keeps its readings accurate. Here’s a simple guide to do it right:

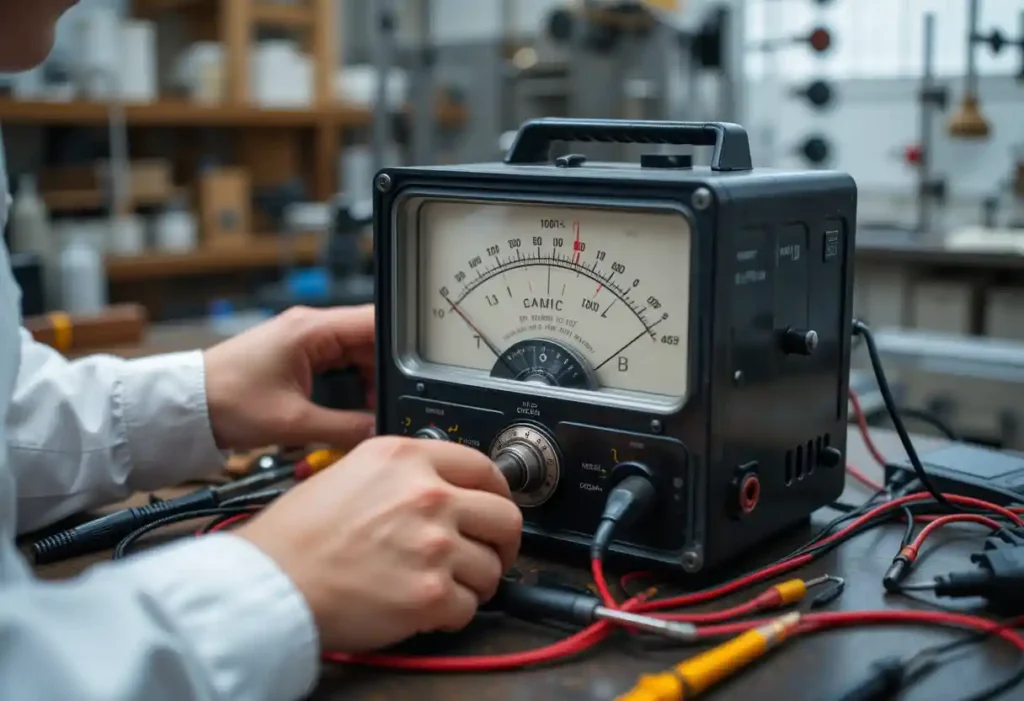

- Gather Your Tools: Grab a calibrated multimeter (as a reference standard), a stable power source, a small screwdriver, and a clean, static-free workspace. A variable resistor or load can help test different ranges.

- Inspect the Instrument: Look for physical damage, loose connections, or a stuck needle. Wipe the exterior with a soft cloth to clear dust that could affect internal parts.

- Set Up the Reference: Connect the instrument in series (for ammeters) or parallel (for voltmeters) with the reference multimeter. Ensure the power source matches the instrument’s range.

- Apply a Known Value: Start with a low, stable current or voltage within the instrument’s range. Compare its reading to the multimeter’s.

- Adjust the Zero Point: If the needle isn’t at zero with no input, use the zero-adjust screw (usually near the bottom) to align it. Turn gently to avoid overwinding.

- Fine-Tune the Scale: Apply known values across the range (e.g., 25%, 50%, 75%, 100%). If readings are off, adjust the calibration screws (often inside the casing) to match the reference. Repeat until accurate.

- Test and Verify: Run tests at multiple points to confirm consistency. Record results for future reference.

Calibration isn’t a one-time thing. Regular checks, especially in busy settings, keep your measurements trustworthy.

Common Errors and Troubleshooting Tips

Even with careful calibration, issues can pop up. Here’s how to tackle common problems:

- Stuck Needle: Dust or debris can jam the mechanism. Gently tap the meter or use compressed air to clear it. If it’s still stuck, open the casing in a clean environment to check for obstructions.

- Inconsistent Readings: Loose connections or worn contacts might be to blame. Tighten terminals and check for corrosion. If the problem persists, the internal coil may need professional repair.

- Zero Drift: If the needle doesn’t return to zero, recalibrate the zero point. Ongoing drift could mean a weak spring or magnet, which may require replacement.

- Overloading Errors: Applying current or voltage beyond the instrument’s range can skew readings. Always verify the range before testing and use protective circuits if possible.

If troubleshooting doesn’t fix the issue, check the manufacturer’s manual or contact a repair service to avoid further damage.

Maintenance Best Practices

Regular maintenance keeps moving iron instruments reliable. Here’s how to do it:

- Weekly Checks: Inspect for dust, loose parts, or wear. Clean the exterior with a dry, lint-free cloth.

- Monthly Calibration: In high-use environments, calibrate monthly to catch drift early. In low-use settings, every 3–6 months works.

- Proper Storage: Store in a cool, dry place away from strong magnetic fields or vibrations. Use protective covers to keep dust out.

- Avoid Overloading: Check the instrument’s range before use. Overloading can damage the internal mechanism.

- Handle with Care: Avoid dropping or jarring the instrument, as its delicate parts are sensitive to shock.

These habits save time and prevent costly repairs, keeping your instruments ready for action.

Comparison with Digital Instruments

| Feature | Moving Iron Instruments | Digital Instruments |

|---|---|---|

| Measurement Type | AC and DC | Primarily DC, some AC models |

| Durability | High (rugged, no complex electronics) | Moderate (sensitive to damage) |

| Calibration Frequency | Monthly or quarterly | Less frequent (self-calibrating) |

| Accuracy | Good, but needs regular calibration | High, often self-correcting |

| Cost | Lower initial cost | Higher, due to advanced tech |

| Ease of Use | Simple, but needs manual calibration | User-friendly, automated features |

| Environmental Tolerance | Resilient to dust, vibration | Sensitive to extreme conditions |

This table shows why moving iron instruments are still valued in rugged settings, even with digital options available. Their durability and simplicity make them a go-to for many tasks.

Frequently Asked Questions

1. How often should I calibrate my moving iron instrument?

It depends on usage. In busy industrial settings, calibrate monthly. For occasional use, every 3–6 months is enough to maintain accuracy.

2. Can I calibrate these instruments without a reference multimeter?

No, a calibrated reference multimeter is essential for accurate calibration. It ensures your instrument’s readings match a reliable standard.

3. What causes a moving iron instrument to give inaccurate readings?

Common causes include dust buildup, loose connections, zero drift, or overloading. Regular maintenance and proper handling can prevent these issues.

4. Are moving iron instruments better than digital ones?

It depends on your needs. Moving iron instruments are durable and handle both AC and DC, but digital meters offer higher accuracy and ease of use. See the comparison table above for details.

5. How do I know if my instrument needs professional repair?

If troubleshooting (e.g., cleaning, recalibrating) doesn’t fix issues like a stuck needle or inconsistent readings, or if the internal coil or spring is damaged, contact a professional repair service.

Wrapping It Up

Calibrating and maintaining moving iron repulsion type instruments doesn’t have to be a headache. With a clear calibration process, quick fixes for common issues, and a solid maintenance routine, you can keep these trusty devices delivering accurate measurements for years. Whether you’re in a hectic plant or a quiet lab, these tips ensure your instruments are always ready. Got more questions or a tricky issue? Drop a comment or reach out—we’re here to help keep your measurements spot-on!